SOME TYPICAL APPLICATIONS OF THE FILTER PRESS FOR FOOD INDUSTRY

The health-promoting effects of omega-3 fatty acids have been known for a long time: People often take cod liver oil, but today the essential omega-3 fatty acid EPA is added to some foods or used as a dietary supplement.

Just like in the food industry, omega-3 fatty acids also play an important role in the pharmaceutical and cosmetic industries. Omega-3 fatty acids lower cholesterol levels and blood pressure, keep the blood fluid, and reduce symptoms of many other diseases.

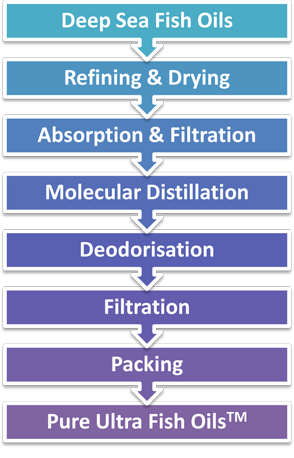

PRODUCTION PROCESS OF OMEGA 3 . FISH OIL

Fish that are not suitable for processing will be graded after being caught and used to produce fish oil. They are crushed and cooked. This causes omega-3 fatty acids found in the fat-storing tissues of fish, to deposit on the surface. They are pumped out and go through further manufacturing processes.

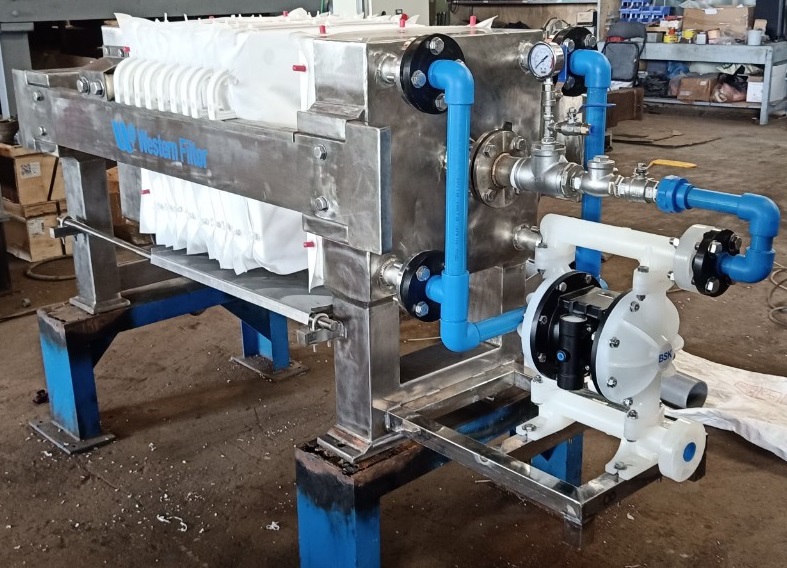

Filter presses are also used in these processes. For example, a filter press is used to separate stearin from omega-3 fatty acids. The remaining fatty acids will pass through the next process. Separated stearin is used to produce candles and soaps.

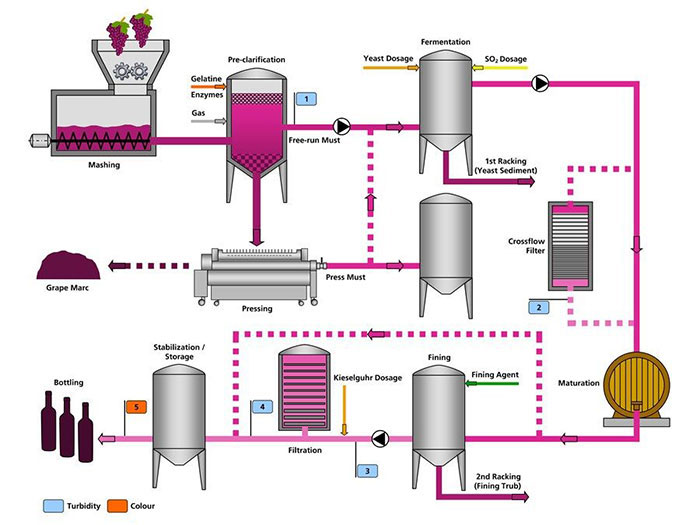

Filter presses are used in winemaking to improve quality. Typical applications of filter presses are filtration of pulp, yeast and dirt. In particular, the final processing stage through the plate frame press often helps increase productivity and save time. Filter aids and filter cloths have been developed specifically for this area. In particular, the membrane plate frame press with a special pressing process that brought the yeast cake to a solid content of approximately 30-40% was successfully used to filter yeast residues.

WESTERN FILTER IN WINE MANUFACTURING INDUSTRY

Filter presses are also used at home in the major German wine regions known for their quality wines. Depending on the quality requirements and the degree of automation, different options are used. From the rust-proof design of the press, the stainless steel housing to the FDA-certified pump and the special recirculating washable (CIP) membrane filters, the full range of options Premium options are used. We are happy to advise you on the best possible filtering for your application. We will even come to your company to survey and assess the situation.

Đang cập nhật…

Đang cập nhật…

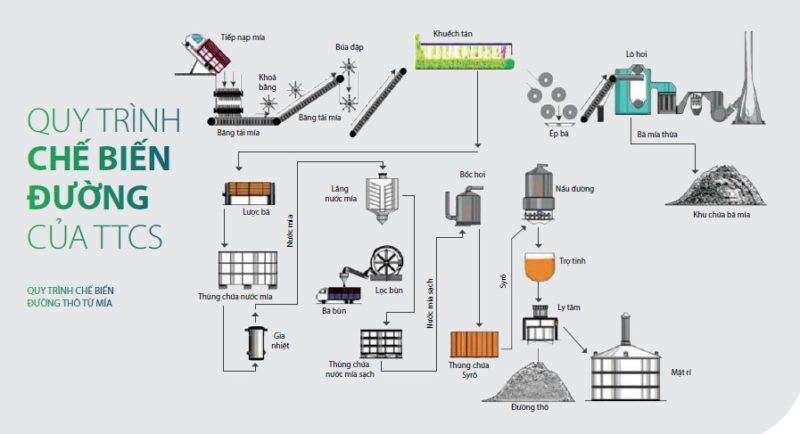

WESTERN FILTER IN THE SUGAR INDUSTRY

The process of processing sugar cane/beet to produce natural sugar can only take place in a short and limited period of time. From the start of the cane/sugar beet harvest to the final processing step, production facilities must operate at peak efficiency. The processing stages take from 12 to 16 weeks, the filter presses used are also subjected to the greatest pressure. Repair or maintenance work is not carried out during this time.

FAST AND EFFICIENT – WESTERN FILTER SLIMING MACHINE WITH HIGH STABILITY

The filter performance requirements in the filter press are very demanding in this area of application. Short cycle time in 24-hour operation and filtration temperature from 80°C to 85°C for best dehydration results. The dry matter content is 70% or more and the residual sugar content in the filter cake is not more than 0.5%.

At this time, the membrane filter press with ABS (surface air blowing technology) technology is especially suitable for this job. In multiple process steps, the filtrate that still has a high sugar content is recovered and recycled.

Filter presses have been used for a long time in the refining of edible oils. Sunflower, rapeseed, and olive oils, when filtered through a filter press, show particularly good filtering properties. These oils are filtered at relatively low temperatures (about 15-30°C) and pressures up to 15 bar.

Special filter cloths and FDA-approved rust-proof filter cloths are used here. To supply materials, we use pneumatic diaphragm pumps that have obtained FDA food safety certification.

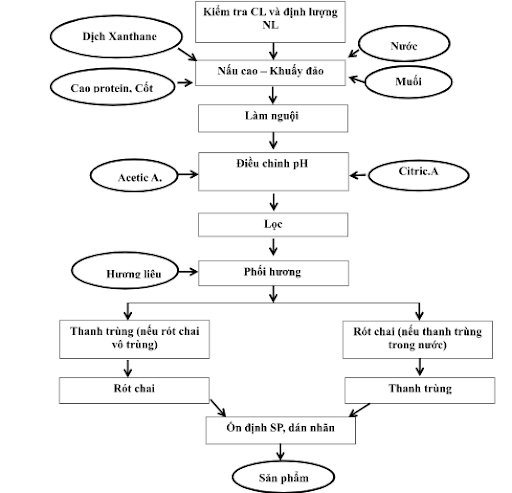

Industrial fish sauce

Fish sauce produced in Vietnam in the 21st century has become technologically advanced, so the juice supplied by the manufacturer is often added to increase production before being bottled and sold, called “industrial fish sauce”.

That preparation method makes the fish sauce more dilute, the color is pale and the smell of fish sauce also fades, so it must be compensated by mixing colors, increasing the consistency, adding flavorings and preservatives to make the finished product eye-catching. As of 2019, the market share of traditional fish sauce is only about 15-20% while industrial fish sauce dominates the absolute majority of consumption.

At the fish sauce filtration stage, the testing requirements set out are to ensure that the elements of the technological process are fully automated, the machine structure must be able to withstand solutions with high salt concentration, the machine must food hygiene and safety

WESTERN FILTER is a pioneer in providing technology lines for fish sauce production companies. Stretching from north to south, our filter lines have high durability and meet the needs of customers.