Are you having trouble choosing the type of diaphragm pump on the market?

1. Diaphragm Pump Introduction

- Unlike other diaphragm pumps on the market, BSK was born with the purpose of overcoming the errors that other diaphragm pumps on the market are making.

- At BSK will help you experience the feeling of operating the pump with optimal efficiency without losing too much energy from the air compressor.

- Thanks to the diaphragm construction closer to the air cap, there is less room for excess air.

- So, in the long run will help you save a considerable amount of operating costs.

For those of you who don’t know, a pneumatic diaphragm pump is a pump with two (or four) diaphragm attached and used with an air compressor to fuel the pump. So you will not have to be afraid of fire or explosion in operation. To know more about what is a pneumatic diaphragm pump, please come to the structure.

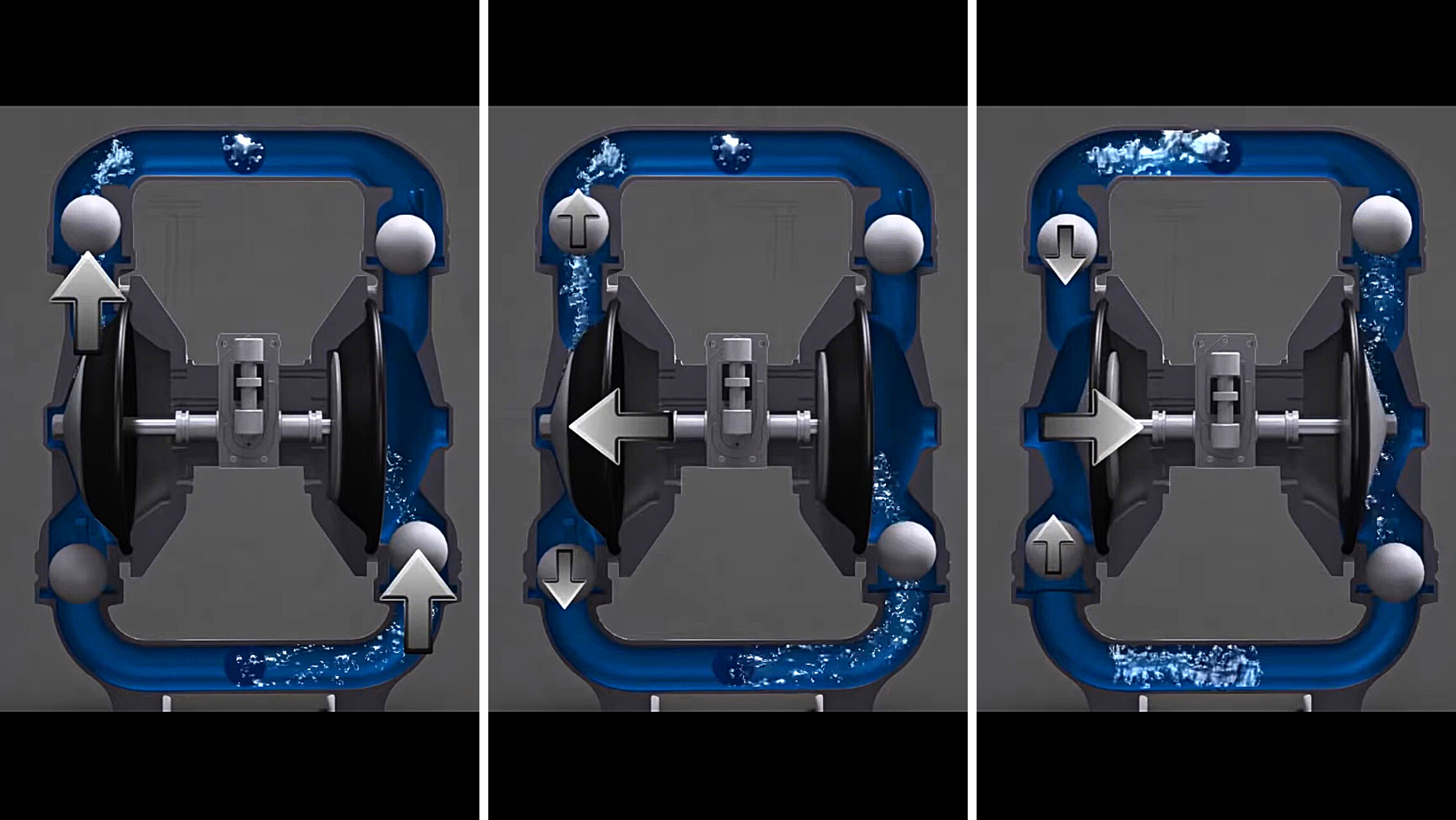

2. Diaphragm pump structure

Pump body: divided into 2 parts

- Fluid side: in direct contact with the liquid to be pumped. Including membrane, ball, ball base.

- Airside: in contact with compressed air, including the air divider, the air distribution valve, the air distribution unit, the valve that divides the air on both sides of the pump chamber, the O-ring sealing, the Gasket.

Air valve: the task of dispersing compressed air to the sides of the air pump chamber to push the pump to work

- Air is compressed, entering the chamber creating a pressure that pushes the diaphragm to the right and out, and the liquid is transferred.

- The right diaphragm pushes to the left, creating pressure so that the liquid is sucked into the chamber to prepare for the next pumping process of the left diaphragm.

Ball and seat:

- Balls are placed on a round base.

- During the suction process, the ball moves up and down creating a gap between them and the fluid passing through.

- In the ejection process, the ball stays close to the sealing base and does not allow the liquid to slide back. From there, create a one-way valve for the diaphragm pump.

Muffler: It is a part to help reduce noise when the compressed air pump is in operation. Parts are sold with the machine, which can be easily removed, installed and replaced.

3. Specifications

MODEL: BA25SS-STT3-A

- Pump body: Inox 316 (SS)

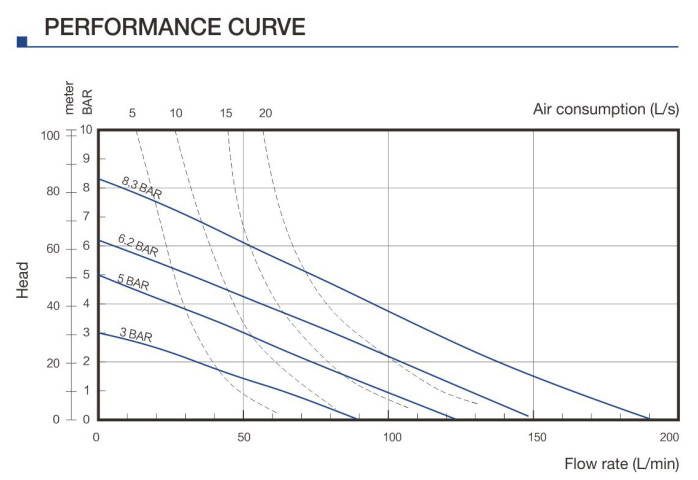

- Max flow: 192 lpm

- Max working pressure: 8.3 bar

- Diaphragm – ball: PTFE

- Suction/discharge port: 1″ BSP

- Maximum dry suction: 6.7 m

- Maximum particle size: 3 mm

- Noise level: 75 dB

- Weight: 14.5 kg

- Brand: BSK – USA

- Warranty: 12 months

- Full CO, CQ documents

4. Advantages

- As you all know, diaphragm pumps are operated by compressed air, so it will help you operate more safely without fear of fire or explosion.

- Not only that, BSK spare parts are 20% less than any other brand of diaphragm pump.

- All parts and components can be replaced individually without replacing the entire air valve, thus effectively reducing maintenance costs.

5. Application

- BSK diaphragm pumps are preferred for use in the oil and gas industry, in chemical and explosive locations such as transporting oil, gasoline, benzene, methanol,…

- Used in food industry: pumping flour, cream, milk, cooking oil, sauce,…

- Cosmetic industry: mixing creams, sunscreens,…

- Producing printing ink, paint solvent paint, ….

- Wastewater treatment industry: pumping chemicals, sludge, pulp,…

>> Similar product: BSK diaphragm pump 1/2″ BP15AL-P991-A

>> Fanpge Facebook: Máy Ép bùn Khung bản – Western Filter Tech

>> Hotline: 0909796560 (Ms. Thanh)

Reviews

There are no reviews yet.