Should you invest in a filter press?

Contents

Apart from the filter press, there are many other options available to handle the daily sludge volume from your factory. These options include sludge drying beds or utilizing methods like drying and incinerating the sludge.

So, why invest in a filter press?

If the sludge is not filtered through a frame filter press, the high moisture content will make it challenging for you in terms of effort and time required for drying and dewatering the sludge.

In reality, the aforementioned methods can be most efficiently implemented after the sludge has undergone the frame filter press stage. At that point, the moisture content of the sludge will be reduced to around 60-75% (depending on the treatment system and different types of sludge).

Combining it with drying methods or sludge drying beds will allow you to achieve the best initial sludge quality. It significantly reduces the cost of sludge collection, transportation, and treatment.

To make a more informed decision regarding investing in a frame filter press, Western Filter will list some things you need to prepare before deciding to invest in a sludge dewatering system!

What do you need to prepare when investing in a filter press?

1. Sludge information

This is the most crucial aspect to help you own a suitable and well-adjusted frame filter press for your system. Why is that? Even a small detail change can result in a change in the filter press’s capacity and the system’s processing outcomes.

If the capacity increases, it will significantly increase the investment value of the frame filter press. The dewatered sludge quality will remain excellent, of course! However, your system may not require such a large press. This will unnecessarily increase the initial investment costs.

Alternatively, a smaller and cheaper press may lead to a decrease in press capacity compared to the system’s requirements. A press with inadequate capacity will make it difficult to thoroughly test and resolve sludge issues for the stakeholders.

You might be wondering about the unmentioned small details, right? Don’t wait any longer, let Western Filter clarify them for you now!

The first important factor – Clear sludge classification

You need to specify how the sludge will be treated with the frame filter press and convey that information to the supplier. This will help the supplier make more accurate decisions regarding the necessary flocculant dosage. Depending on the sludge type, you may or may not need flocculants while still achieving the desired dewatered sludge solidity.

Some common types of sludge can be classified as follows:

- Raw sludge

- Biological sludge

- Mixed sludge

- Digested sludge

- Physicochemical sludge

- Mineral sludge

What is the sludge concentration (% DS)?

This parameter almost determines 80-90% of the press capacity. Clarify this information with the equipment supplier. They will help you make an excellent choice for a frame filter press that will be a long-term solution for you.

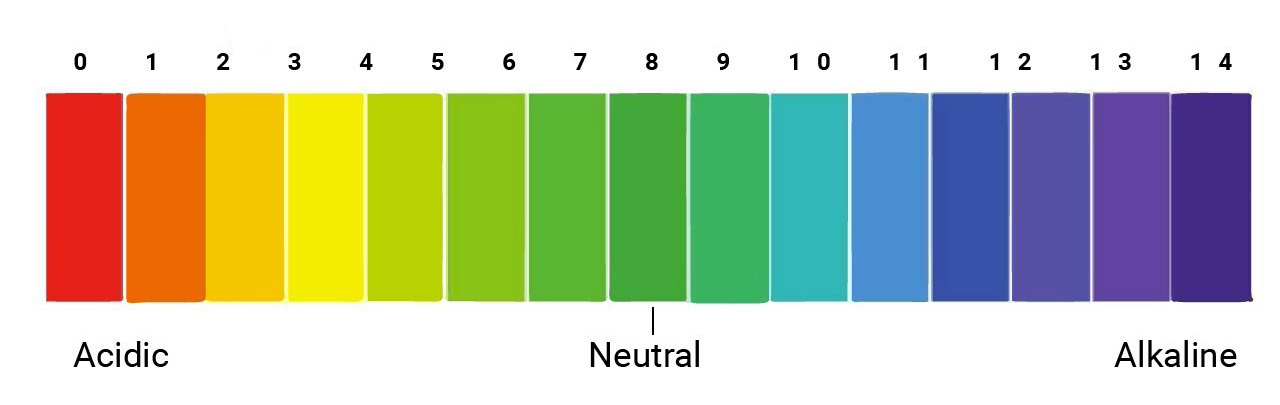

Basic properties: Base or Acid

Depending on this sludge property, the filter press manufacturers will provide different filter cloths for your filter press. This will help maximize the press’s performance by enhancing the self-falling state of the filter cakes, making it easier for operators during the manual cake discharge process (in the case of manual plate separation).

It would be even better if you can determine the pH level of the discharged sludge. The more input data you have, the more accurately you can select the appropriate filter cloth and other corresponding parts of the press, tailored to the users’ needs. Properly used filter cloths are usually durable, contributing to reducing replacement and.reducing replacement and.

Does the surrounding environment cause significant corrosion?

Corrosion can have a severe impact on the machine base and body, leading to serious consequences. Typically, machines can last 10 to 20 years, but under corrosive conditions, the opposite is true. Therefore, we always have measures in place to help you make the best choice. If your sludge falls into this category, you can learn more about the Stainless Steel Filter Press designed by Western Filter specifically for your wastewater treatment system.

Is the sludge discharged regularly every day?

Once again, this combined factor helps you determine the machine’s capacity. Knowing this specific value ensures that your sludge dewatering machine will never experience malfunctions or inefficiency due to overload.

2. Machine placement

- The closer the filter press is placed to the sludge tank, the better. It helps reduce pressure loss when the sludge is pumped through the pipes.

- The working area should be at least 3 meters away from the machine to allow operators to operate comfortably and facilitate the transportation of filter cakes.

- The minimum area required to place the machine should have an additional 40cm clearance around the machine.

In addition, you can equip yourself with some basic knowledge to feel more confident in your investment decision.

You can refer to the wastewater sludge treatment solutions provided by Western Filter in Nhơn Trạch for an overview of the equipment you are considering investing in!

Conclusion

Investing in a frame filter press for wastewater treatment plants is crucial, both legally and in terms of usage requirements. However, everyone may have different perspectives and opinions on sludge treatment, leading to different ways of thinking and decision-making. Most of all, each of us wants to aim for the good, the appropriate, the common benefit for our business.

In terms of sludge treatment, Western Filter with its world-class expertise and experience is always ready to accompany every individual and every business. Closely follow the project, orient the process, provide solutions, and quickly and completely deploy. From there, shortening time and effort, helping you solve all problems of sewage sludge simpler and more convenient.

Contact now: 0909796560 (Ms. Thanh) for more advice on your problem!

You may be interested: Renting a membrane filter press

Visit fanpage Facebook of Western Filter Tech