FDA & 3A Diaphragm Pumps BSK – USA

Why use FDA & 3A certified diaphragm pump?

Using FDA & 3A certified diaphragm pumps in food and beverage applications brings many important benefits to your business, as follows:

- Ensuring food safety: Diaphragm pumps are designed to meet FDA’s high quality standards. This ensures that the materials used in the pumps do not harm human health when used to pump food, pharmaceuticals, and biologics.

- Ensuring product stability and quality: FDA pumps can pump thick, viscous, or temperature and pressure-sensitive liquids. This helps minimize errors and ensure stability and quality of the product.

- Easy to clean and maintain: FDA diaphragm pumps have a simple design and are easy to maintain. This helps reduce the risk of contamination and protects the safety and quality of the product.

- Cost savings: Using FDA certified diaphragm pumps helps save costs because the pump’s components and materials are durable, less prone to damage, and have a long lifespan.

Using FDA & 3A certified diaphragm pumps in the food, pharmaceutical, and biotech industries is essential to ensure product safety and quality, reduce costs, and increase production efficiency.

Difference between FDA diaphragm pump and common diaphragm pump?

It is an obvious fact that there are many differences between the FDA & 3A diaphragm pump and the common pneumatic diaphragm pump in terms of design, materials and quality standards.

- Design: FDA diaphragm pumps are specially designed to meet hygiene and safety standards in the food and beverage industry. The pump parts are made of food-safe materials and have a simple design that is easy to disassemble for cleaning and maintenance.

- Materials: FDA diaphragm pumps are made of food-safe, corrosion-resistant, and antibacterial materials, ensuring safety and hygiene for food and beverage products. In contrast, common pneumatic diaphragm pumps can use various materials, depending on the needs and applications of the product.

- Quality standards: FDA diaphragm pumps must meet the strict standards of the US Food and Drug Administration (FDA) and other evaluation organizations such as 3A, EC 1935/2004 to ensure safety and hygiene for food and beverage products. In contrast, common pneumatic diaphragm pumps do not have strict requirements for hygiene and safety in the food and beverage industry.

Therefore, FDA diaphragm pumps are widely used in the food and beverage industry to ensure safety and hygiene for food and beverage products.

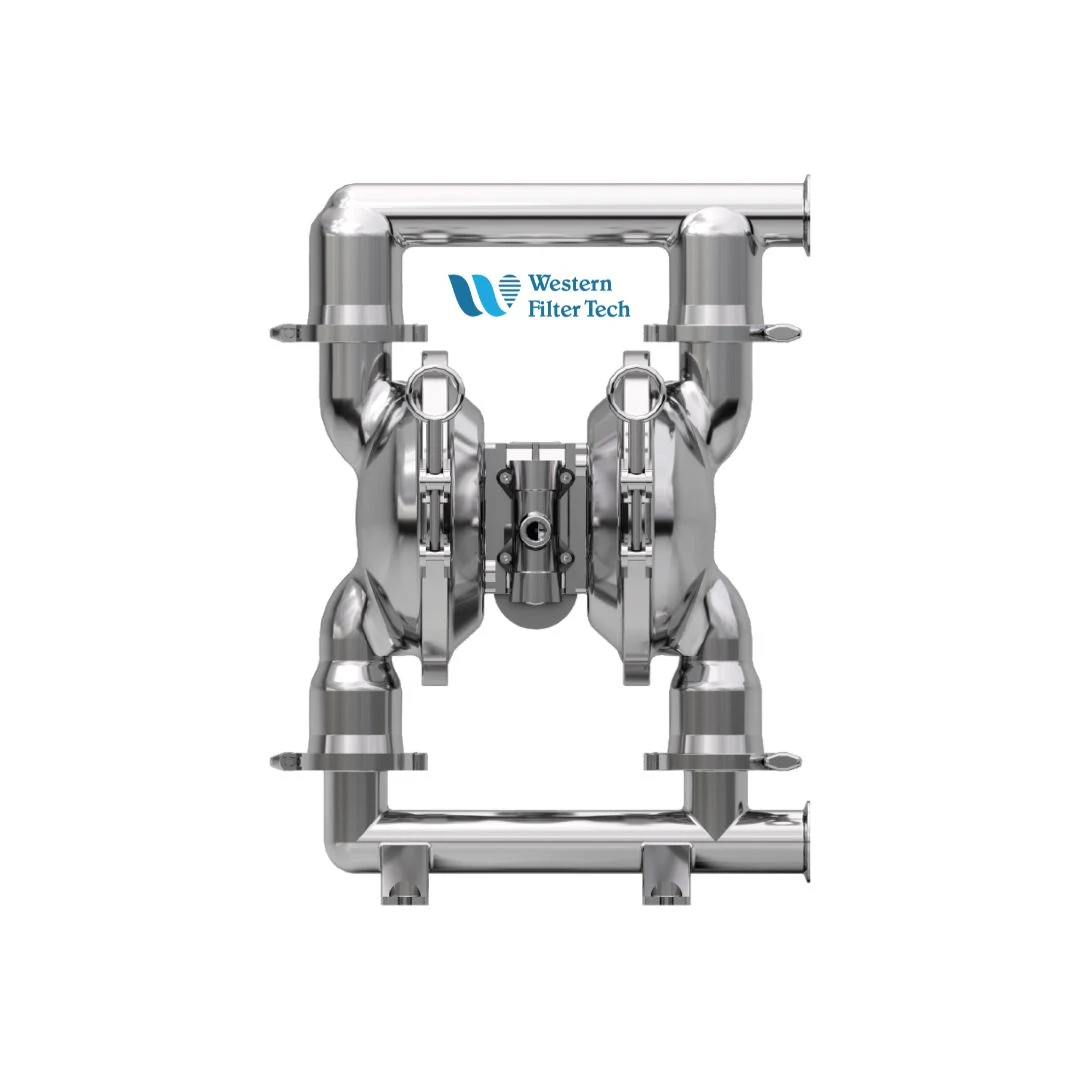

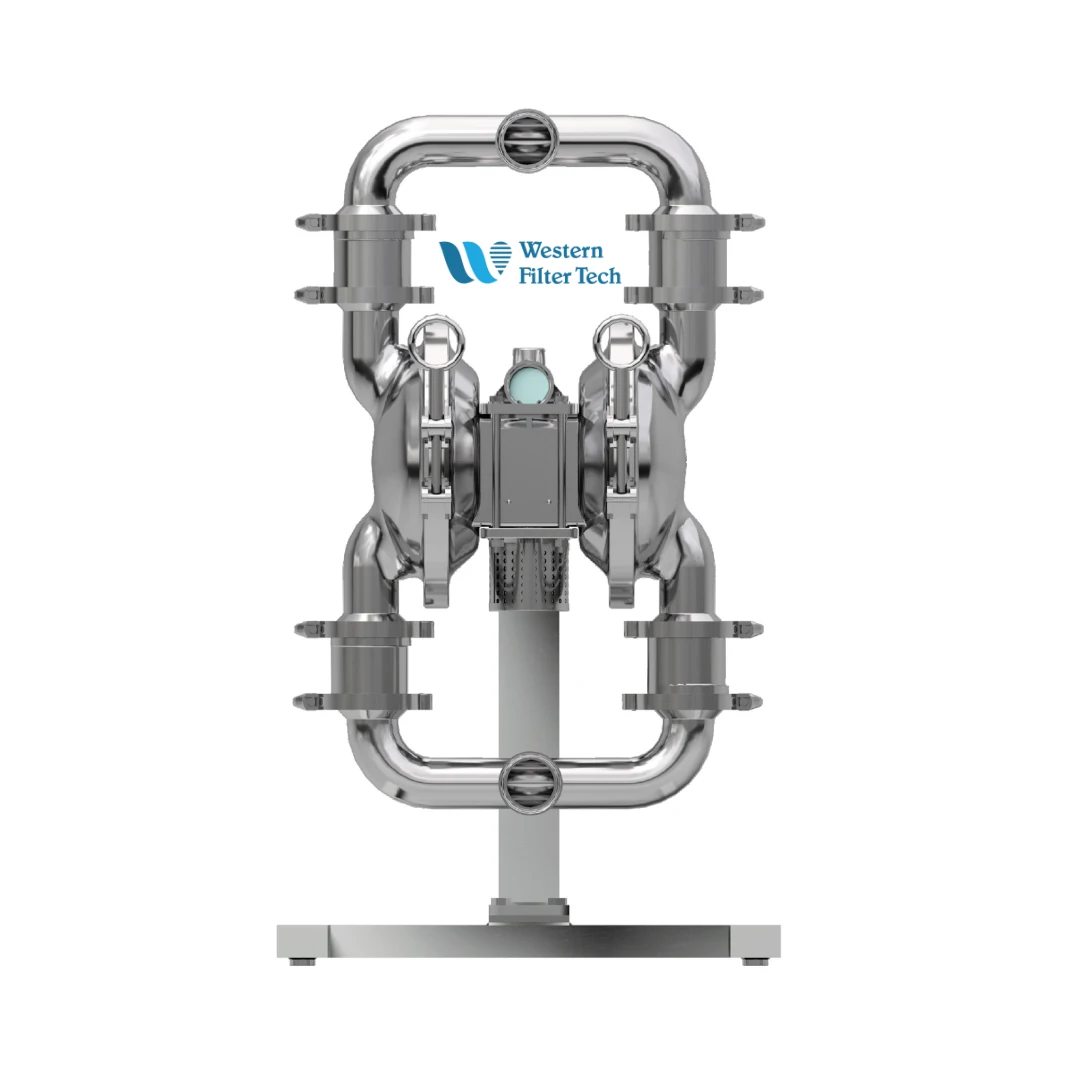

Technical specifications

- Model: FD77-STT7-E

- Pump Body: Stainless steel 316

- Maximum flow rate: 621L/min

- Maximum working pressure: 8.3 bar

- Diaphragm material: PTFE – Stainless steel

- Inlet/outlet size: 2.5 inch (Clamp)

- Maximum suction height (dry suction): 5.6 m

- Maximum particle diameter: 9.5 mm

- Noise level: 75 decibels

- Weight: 47 kg

- Brand: BSK – USA

- Warranty: 12 months

- Complete CO, CQ documents

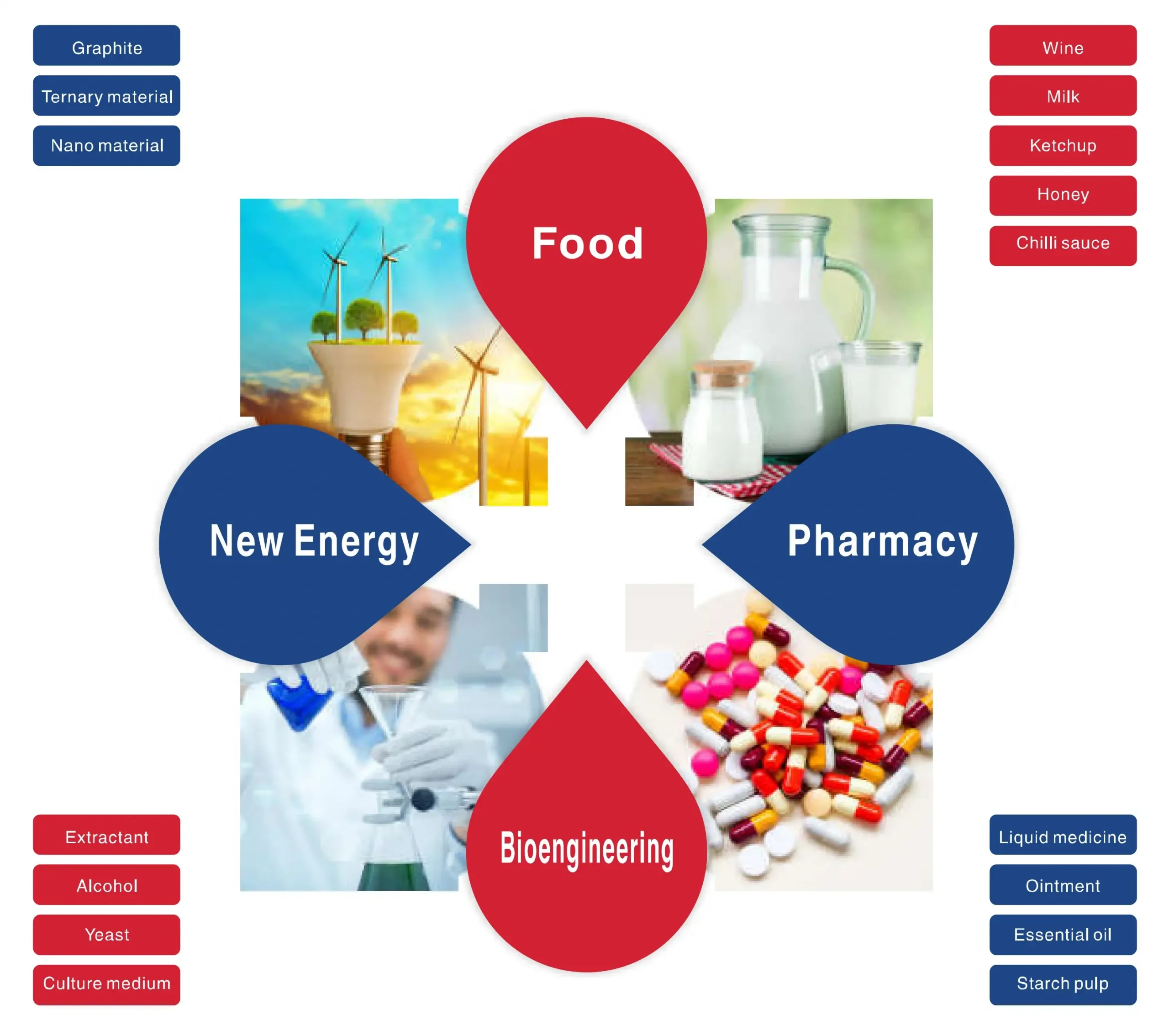

Applications

FDA & 3A diaphragm pumps are versatile pumps widely used in the food and beverage industry. Here are some common applications of this product:

- Pumps for Milk and Milk Products: FDA & 3A Food Grade Diaphragm Pumps are used for pumping milk and milk products such as yogurt, cream, butter, cheese, etc.

- Beverage Pumps: This equipment is used for pumping various types of beverages such as soft drinks, juices, fruit drinks, etc.

- Vegetable Oil Pumps: This product is used for pumping various types of vegetable oils such as cooking oil, soybean oil, sunflower oil, etc.

- Water and Other Liquid Pumps: FDA & 3A Food Grade Diaphragm Pumps are also used for pumping water and other liquids such as soap, detergents, seawater, etc.

- Pumps for Mixtures: This product has the ability to pump mixtures such as powder, concentrated mixtures, etc.

- Frozen Food Pumps: This equipment can pump frozen food products such as seafood, meat, vegetables, fruits, etc.

- Medical Product Pumps: FDA & 3A Food Grade Diaphragm Pumps are also used for pumping medical products such as medicines, sterilizing solutions, etc.

Application of FDA & 3A food grade diaphragm pumps in fields that require high safety and health standards for consumersApplication of FDA & 3A food grade diaphragm pumps in fields that require high safety and health standards for consumers.With its flexibility and versatility in application, FDA & 3A food grade diaphragm pumps are an important and indispensable product in the production and processing of food and beverage products.

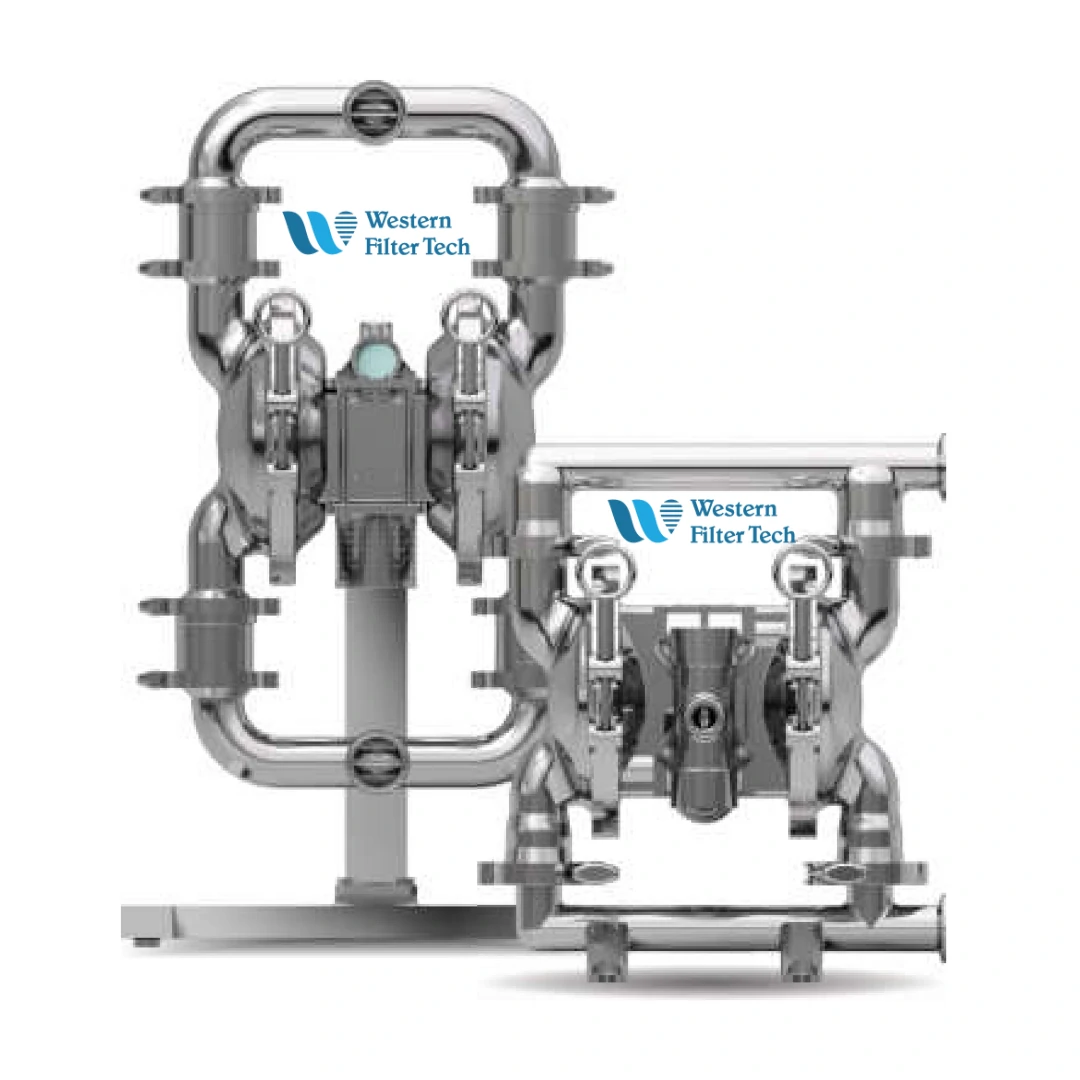

They help optimize the production process, improve efficiency, and ensure the quality of the final products. As the leading distributor of BSK – USA in Vietnam, Western Filter Tech is pleased to offer our discerning customers our carefully selected products.

With a wide range of high-quality diaphragm pump options and readily available stock at competitive prices, it is the perfect choice for any business seeking to learn about and apply FDA & 3A diaphragm pumps to their production models.

>> Contact our hotline for more information: 0909796560 (Ms. Thanh)

>> Similar product: FDA & 3A Diaphragm Pumps – BSK 1″ FD50-STT7-E

>> Fanpge Facebook: Máy Ép bùn Khung bản – Western Filter Tech

Reviews

There are no reviews yet.