PP membrane filter press X1500 – Western Filter

SPECIFICATION OF PP MEMBRANE FILTER PRESS X1500

- Basic features like a regular plate frame

- Resistant to acids, alkalis and temperatures (70 degrees Celsius)

- Inlet pressure up to 20 bar by water

- Faster filter press cycle than conventional plate frame

- Low mud cake moisture less than 30% for some industries

- Elasticity and long life

APPLICATION OF PP MEMBRANE FILTER PRESS X1500

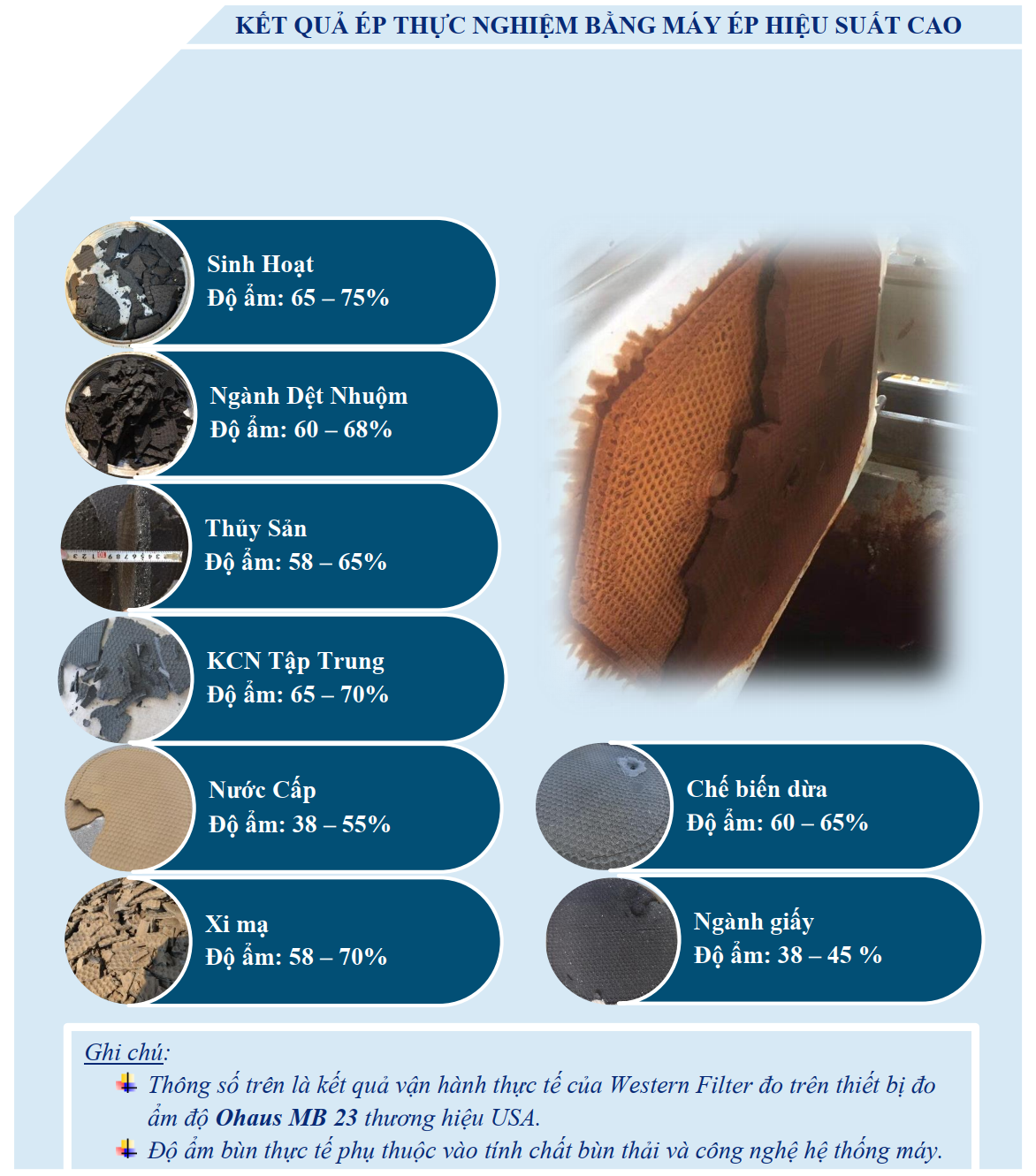

PP membrane filter press is applied in many different fields thanks to the application of advanced filter press technology from Europe. With the superiority of this technology, we are gradually realizing the goal of minimizing moisture after the filtration process.

ADVANTAGE OF PP MEMBRANE FILTER PRESS X1500

As the optimal technology in separating liquid-solid phases, high-performance sludge dewatering machines are widely used in the food, heavy industry and mining industries:

- The highest filter press efficiency in current filter press technologies

- Simple, solid mechanical design

- Low maintenance cost

- Simple operation mode, less use of coagulant chemicals

STRUCTURE OF PP MEMBRANE FILTER PRESS X1500

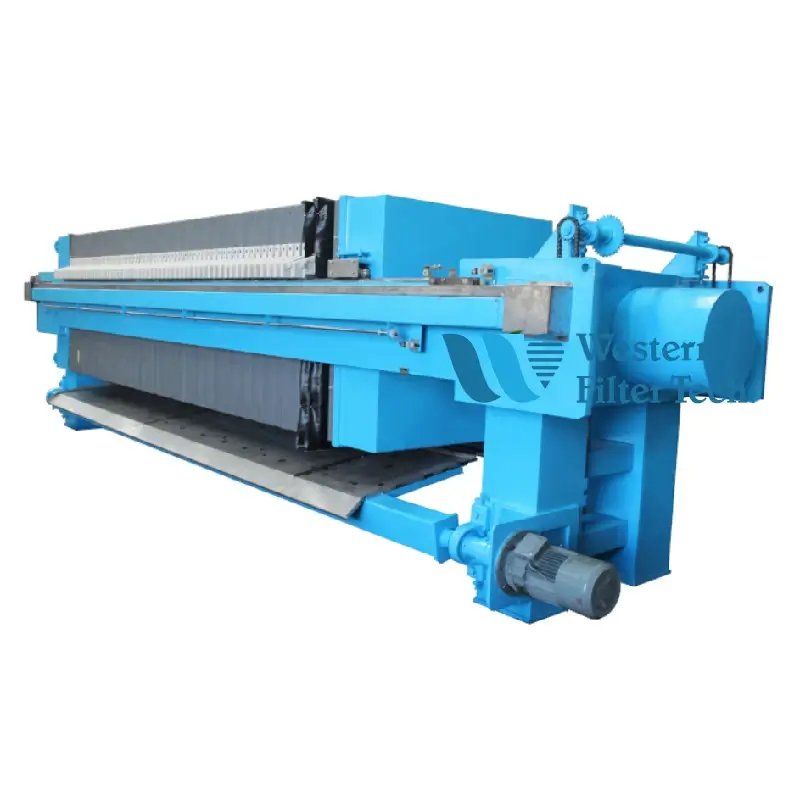

The WESTERN FILTER high-performance filter press is researched and manufactured by our R&D engineers based on specialized simulation software. Based on this, we calculate the load range and durability of the chassis before production.

With applications for many different industries, the entire chassis is coated with multiple layers of epoxy to resist mechanical and chemical corrosion, all hydraulic lines are selected suitable for high frequency of daily work.

For many years of establishment and development, WESTERN FILTER is one of the leading brands in researching and manufacturing filter presses for many different fields.

The PP membrane filter press – WESTERN FILTER perfectly fulfills the most demanding demands in terms of filter press performance and equipment quality.

Currently, we focus on supplying this machine line to most of the heavy industries (metallurgy, mining…), manufacturing and processing industries (aquaculture, tapioca starch, cashew oil, paper and pulp). …) to ensure the best performance based on the following factors:

- The whole system is controlled via HMI, SCADA.

- Using 15 – 20 bar high pressure hydraulic system.

- Specialized filter cloth for each industry.

- Simple operation mode, less use of coagulant chemicals.

- The time is shortened to the maximum compared to the current filter plate lines

TECHNOLOGY TO SIMULATE THE OPERATION OF THE ENTIRE SYSTEM

WESTERN FILTER is a pioneer in Vietnam in simulation technology for installation and operation of virtual systems. All equipment will be arranged to install 3D in the simulation space.

Different from previous simulation systems, the entire construction and installation process is selected and arranged by the customer right in the virtual 3D space, shortening the time and cost in the construction and selection the device.

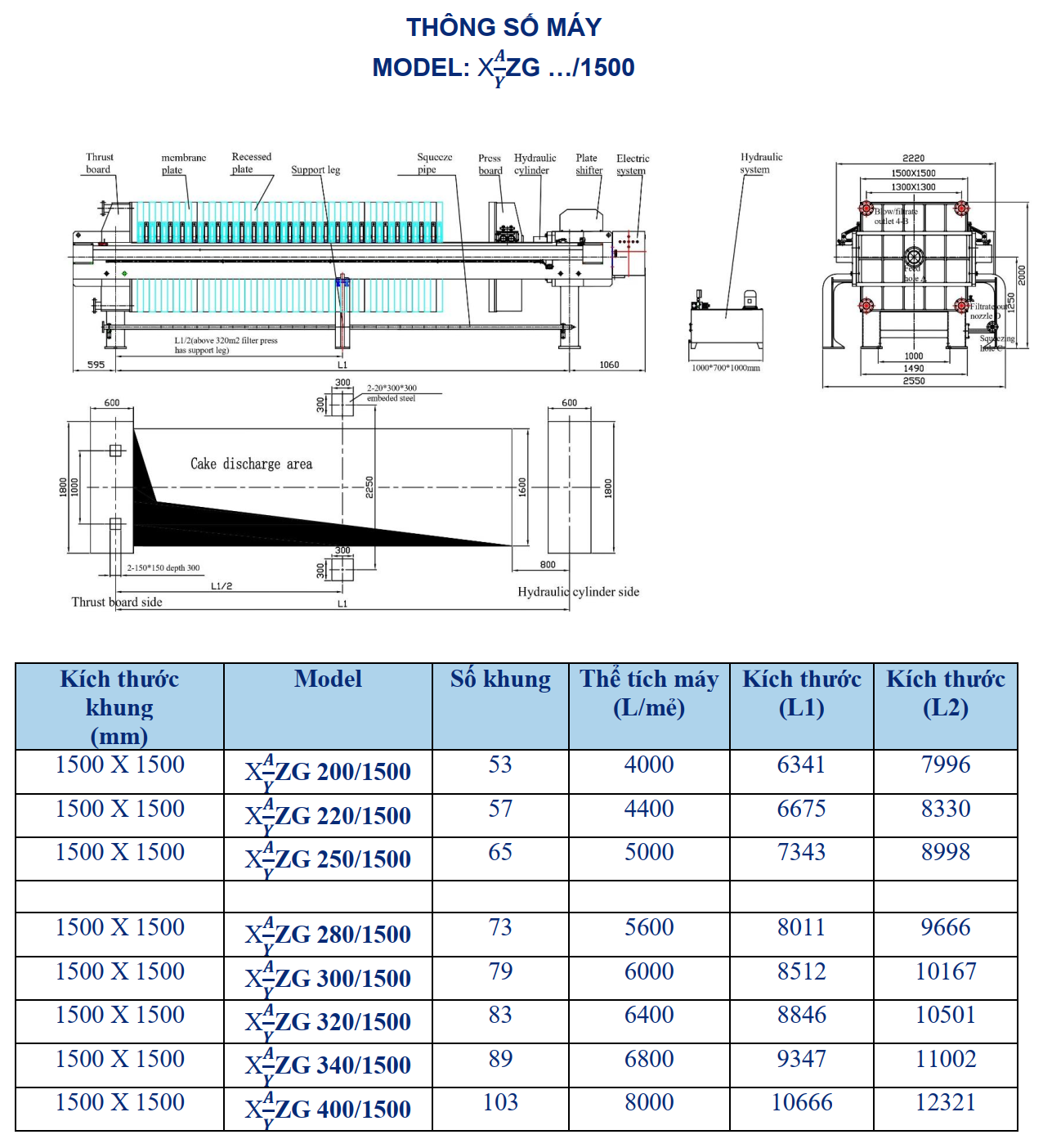

THỐNG SỐ CỦA MÁY ÉP BÙN KHUNG BẢN HIỆU SUẤT CAO X1500 SERIES:

The PP membrane filter press has a simple structure, consisting of many filter plates covered with a layer of filter cloth. Depending on the capacity of the plate frame mud press, the number of filter plates will change. The filter plates will be compacted to form many filter compartments containing sludge.

The sludge is coagulated and flocculated before being pumped into the filter chambers of the machine by a high-pressure pump (pneumatic diaphragm pump – or screw pump).

During the process of feeding slurry into the machine, on the surface of the filter cloth in the cavity, separation will occur. Solid sludge particles will be retained on the surface of the filter cloth while water will penetrate and escape through the pipeline.

When the sludge has accumulated and filled the filter chambers, the sludge pump is turned off. The plates will be separated automatically or manually to remove the sludge. The filter cloth will be washed automatically or manually to continue the new filter cycle.

With the production characteristics and economic conditions in Vietnam today, the frame mud press designed and manufactured by Western Filter Technology Co., Ltd is a reasonable choice when the product price is low. much cheaper than imported products.

The design and manufacturing characteristics of the machine are relatively suitable for the current scale of sludge treatment in Vietnam, while the quality of the equipment is not inferior to that of imported products and especially imported products. After-sales service warranty policy is extremely fast and professional.

WESTERN FILTER TECHNOLOGY warranty one year filter press machine as well as for products after handover and technical support to solve all problems arising when using the company’s products. Products with manufacturing defects will be refunded according to the agreed contract value.

Model selection of PP membrane filter press X1500

- Manual operation

- Semi-automatic operation

- Automatic operation

We are proud to be a professional manufacturer of slurry filter presses in Vietnam with a team of dedicated and well-trained engineers, so your company can rest assured in the stages of technology consulting, Equipment selection as well as after-sales service are carried out by us with the highest concentration and responsibility.

We have a sample filter press machine that can be tested for free before the company decides to invest. Contact Western Filter Technology for all your sludge problems.

Video for automatic filter cloth washing – Western Filter

>>> Similar product: Máy ép bùn khung bản hiệu suất cao X1250 Series – Western Filter

>>> Fanpage Facebook: Máy Ép bùn Khung bản – Western Filter Tech

Reviews

There are no reviews yet.