The unit proposes to rent a membrane filter press

Contents

Western Filter Tech Co., Ltd

General introduction about the project

1. Scale summary

- Proposing the treatment of sewage sludge for the printing ink wastewater treatment system in Duc Hoa 3 Industrial Park.

- Rent a membrane filter press to run a test sample to determine the moisture content of the mud cake.

2. Objectives of the project

- Find the optimal solution to treat all sludge generated in the wastewater treatment process of the plant.

- Bring the mud moisture after pressing to about 60-70%.

- Automate machines to reduce labor costs.

3. Factory situation

4. Assessment

Through the survey results and the input wastewater data table of the plant, the following points should be noted:

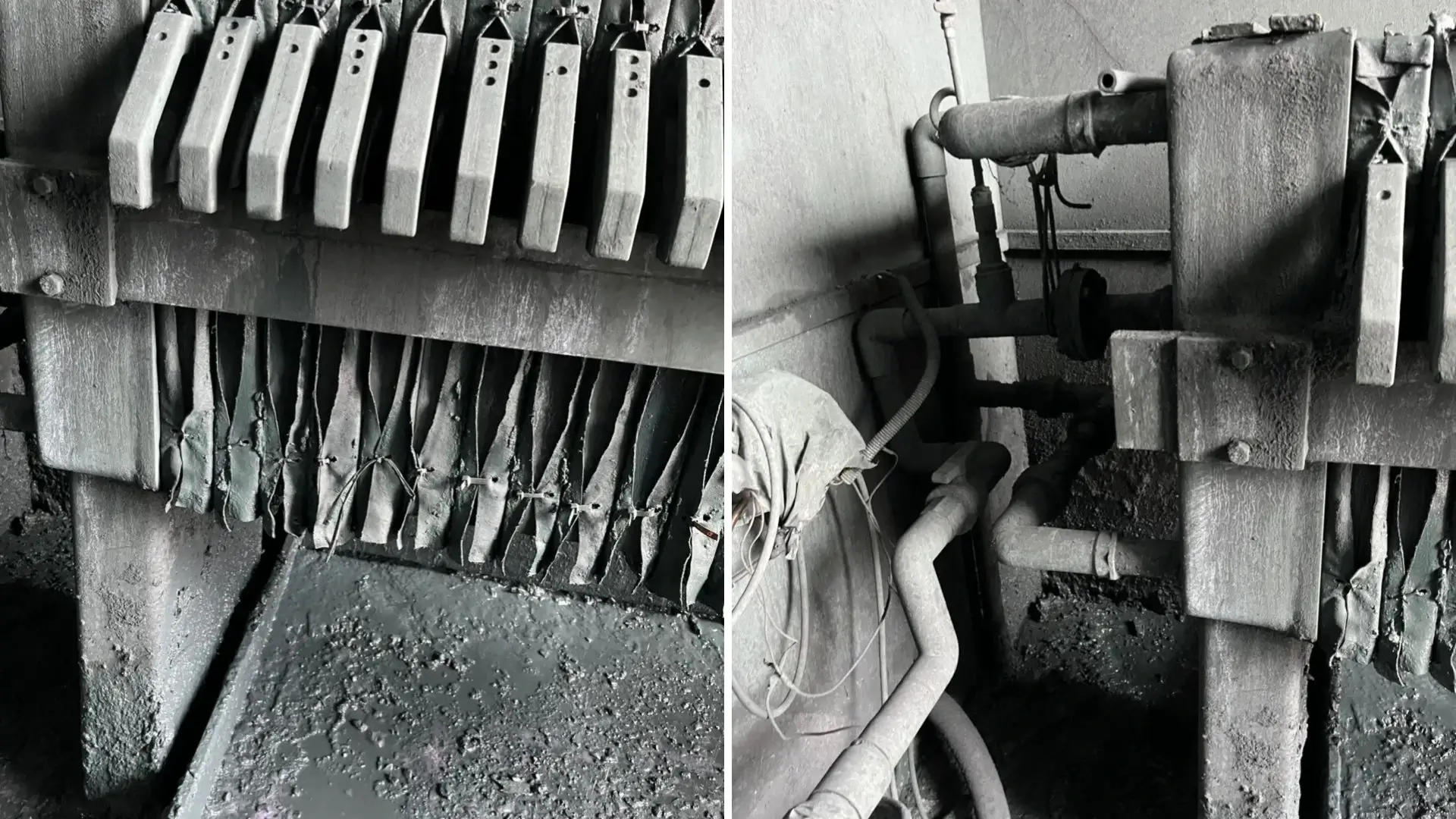

- The sludge pressing system at the plant is inefficient, and the filter cloth and hydraulics show signs of serious deterioration.

Inefficient machinery leads to a large accumulation of sludge in the plant. - In addition, high humidity makes it difficult to pack for shipping.

- The treated sludge is not closed, leading to the generation of bad odors for the surrounding environment, greatly affecting the health of the operator.

From the above points to meet the requirements of treating all sludge, saving operating costs and long-term calculations for the plant environment as well as the health of operators, it is necessary to replace the filter press existing version by system of automatic membrane filter press.

With the customer’s expectation of moisture commitment, Western Filter conducts a rental service of membrane filter press within 2 days.

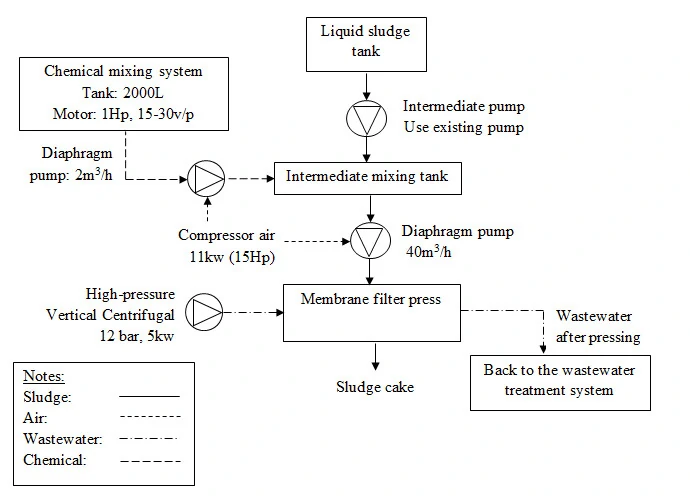

Proposing a treatment plan with a membrane filter press

1. Technological diagram suitable for sludge treatment system

2. Rent a membrane filter press to determine the moisture content

Specifications:

- Machine volume: 50L/batch

- Plate frame: 630x630mm

- Number of plate frame: 7 pcs (including beginning and end plate frame)

Main material:

- Machine frame: Made of tempered steel, 4-layer epoxy paint, chemical and mechanical corrosion resistance

- Filter cloth: PP plastic fiber

- Filter frame: PP plastic

- Membrane frame: PP + PTE plastic

Control cabinet:

- PLC: Siemens

- Electronic module: Schneider

- Voltage: 380V/3phase/50Hz

Hydraulic cylinder:

- Cylinder: 27SiMn . weldless steel tube

- Piston: 45# steel, 0.06mm Chrome plated

- Heat treated to harden

Machine size and weight:

- Length: 5895mm

- Width: 1240mm

- Height: 1200mm

- Weight: 3983 kg

Main machine integration includes:

- Automatic frame splitting system.

- Separation mechanism: Separate each plate frame with a pull hook

- Chain conveyor: 304 . stainless steel

According to the main machine include:

- Hydraulic oil

- Machine operating instructions

Find more about Membrane filter presses series

3. Diaphragm pump

- Function: pump slurry with suitable flow and pressure to the slurry press

- Type: Pneumatic Diaphragm Pump Type

- Origin: BSK (CO China, CQ-test report BSK-USA)

- Number of machines: 1 machine

General specifications:

- Type: Pneumatic diaphragm pump

Flow: 20 m3/h

Max head: 8.3 bar

Fluid: Liquid sludge

Pump body: PP plastic

Inlet/outlet connection: 1″ (DN25) thread

Learn more about BSK diaphragm pump 1″

4. Sludge cake results after running the rental filter press

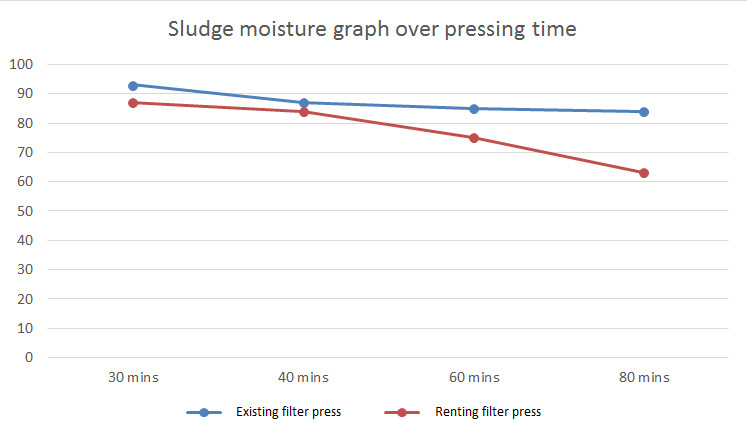

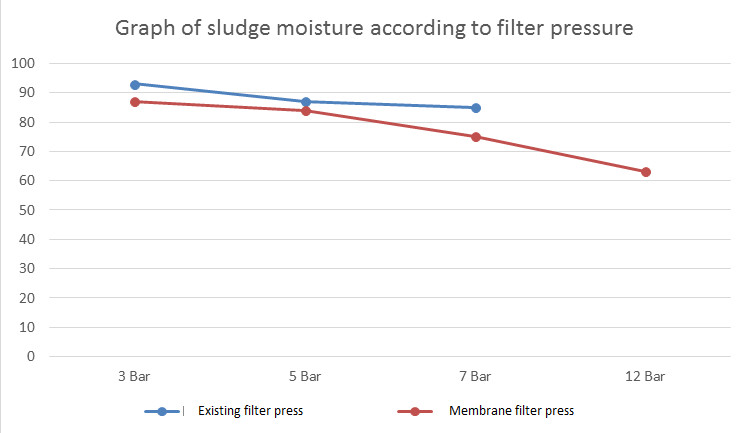

5. Compare the results

The moisture content of the sludge cake was determined by a drying balance in the laboratory of Western Filter Technology Co., Ltd, giving the following results:

For the existing filter press machine system, the filter press pressure and the original technology lead to the pressing pressure that depends on the diaphragm pump system (up to 7 Bar) which cannot be raised to 12 bar at all, so the sludge moisture is still very low. compared to high performance machines.

This difference confirms that for a membrane filter press, the operator can completely control the filter press pressure of the machine and produce the desired sludge moisture result.

Conclusion

Through the process of renting a mud press, we can see that the output mud cake of the ink wastewater treatment system in Duc Hoa 3 Industrial Park still retains extremely good moisture without using any coagulant chemicals.

Especially, the rental fee will be completely deducted from the new machine contract. There for, the rental service of the membrane filter press at Western Filter is completely free!!!

Because our goal is always want to bring to our customers the most suitable products for each separate treatment system, of each different type of processing technology.

With an experienced technical team, it will definitely help you find a solution that is more effective than you think, while ensuring economic balance and long-term smooth operation.

We do not sell FILTER PRESS. All the values that we desire are to bring you sludge treatment solutions, enthusiasm, reputation and customer satisfaction!

>> Visit Western Filter Tech’s fanpage Facebook

>> Contact now: 0909796560 (Ms. Thanh) for a free consultation!