Chamber filter press X920 – Western Filter

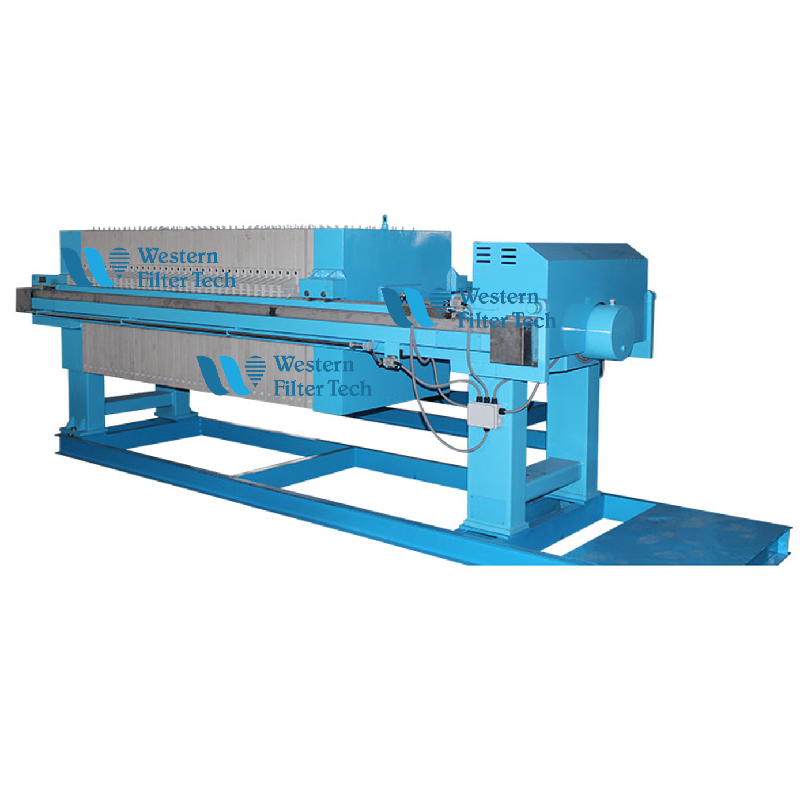

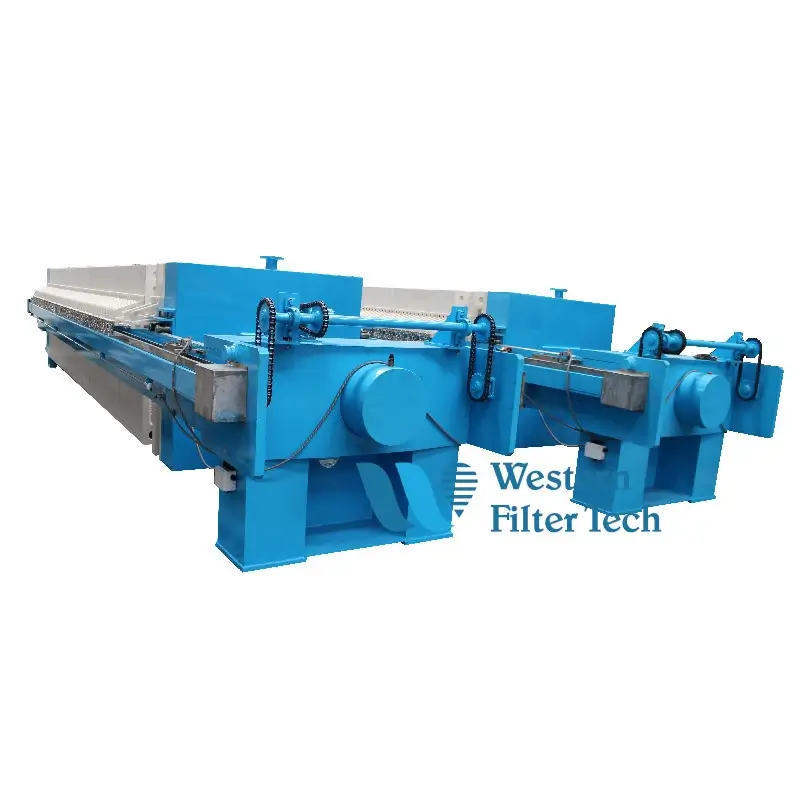

Photo of Chamber Filter Press X920 – 40m2 Produce for Textile Dyeing Company Project – Trang Bang Industrial Park

FILTRATION PRINCIPLE OF CHAMBER FILTER PRESS X920

At the beginning of the filtration cycle, the press and the filter plates are closed by a (hydraulic) locking cylinder. The closing cylinder presses the filter plates against each other via the pressure plate and increases the hydraulic pressure accordingly up to the required nominal closing pressure.

Due to the design, a chamber is formed between the individual filter plates, which represents the process chamber. The suspension to be filtered is pumped into the chambers with a suitable feed pump through the turbidity inlet at the feed stand and concentrated there. Depending on the respective application, the filter plates are lined with special filter cloths which visibly retain the solids during the flow, taking into account the process characteristics.

DISCHARGE OF THE FILTRATE / EMPTYING OF THE CHAMBERS

The filtered and clear liquid (filtrate) is discharged along a channel system (open filtrate outlet) into the laterally mounted filtrate channel. A closed filtrate outlet is also available as an option. The solid material, on the other hand, remains in the plate chamber as a solid filter cake. The increasing feed pressure compresses and dewaters the resulting filter cake in the chamber.

Once the throughput has fallen to a predetermined minimum, the pressure has increased significantly and the individual chambers inside the filter plates are completely filled with the filter cake, the filtration process is complete. To empty the chambers, the closing pressure of the filter press is released, the filter press is opened and the cake is removed from the filter cloths. The filtration cycle is then repeated.

WESTERN FILTER TECHNOLOGY warranty one year filter press machine as well as for products after handover and technical support to solve all problems arising when using the company’s products. Products with manufacturing defects will be refunded according to the agreed contract value.

Model selection of chamber filter press X920

- Manual operation

- Semi-automatic operation

- Automatic operation

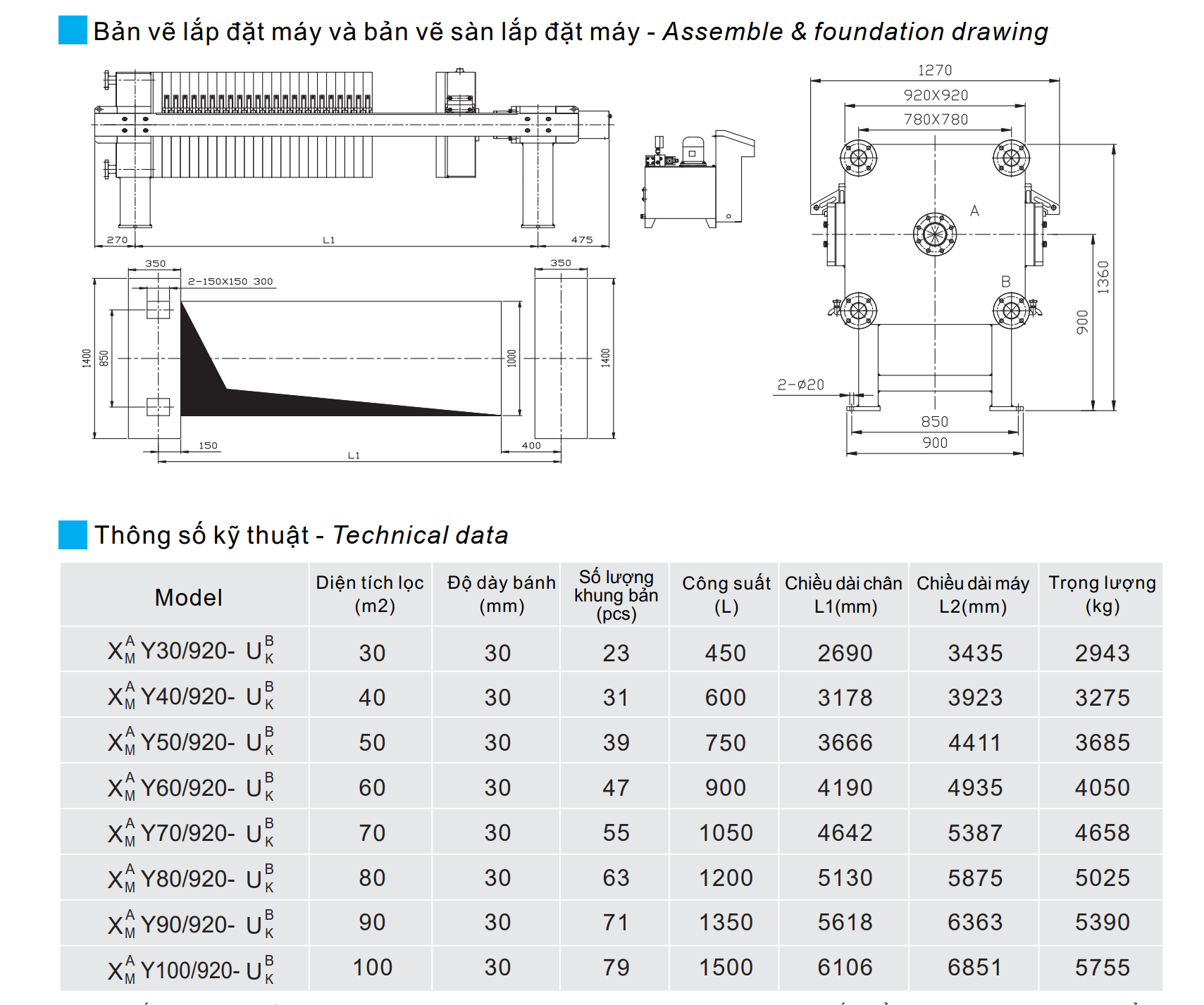

Specifications of chamber filter press X920

Technical data:

Common form chamber filter press X920 Model: XAM*/920-UBK

- Model: XAM*/920-UBK

- Filter area: 30-100(m2)

- Thickness of filter cake: 30(mm)

- Thickness of filter plate: 60(mm)

- Capacity: 450-1500(m3)

- Dimension L1: 2690-6106(mm)

- Dimension L2: 3435-6851(mm)

- Weight machine: 2943-5755(kg)

- The inlet mud pressure can be up to 10bar, suitable for small projects and for testing machines.

- Table of machine dimensions, model selection of chamber filter press X630 Series and other specifications as follows:

Assemble and foundation drawing of chamber filter press X920

- We are proud to be a professional manufacturer of slurry filter presses in Vietnam with a team of dedicated and well-trained engineers, so your company can rest assured in the stages of technology consulting, Equipment selection as well as after-sales service are carried out by us with the highest concentration and responsibility.

We have a sample filter press machine that can be tested for free before the company decides to invest. Contact Western Filter Technology for all your sludge problems.

Video for machine operation principles of Stainless steel filter press – Western FIlter

Video for automatic filter cloth washing – Western Filter

>> Similar product: Chamber Filter Press X800 – Western Filter

>> Fanpage Facebook: Máy ép bùn Khung bản – Western Filter Tech

Reviews

There are no reviews yet.