Sparklers filter – Western Filter

1, Introduction Sparklers filter

Sparklers Filters or Stainless Steel Sparklers Filters are a type of filters used for solid-liquid and impurity filtration in the chemical and food processing industries.

2, Structure and Working Principle

Structure

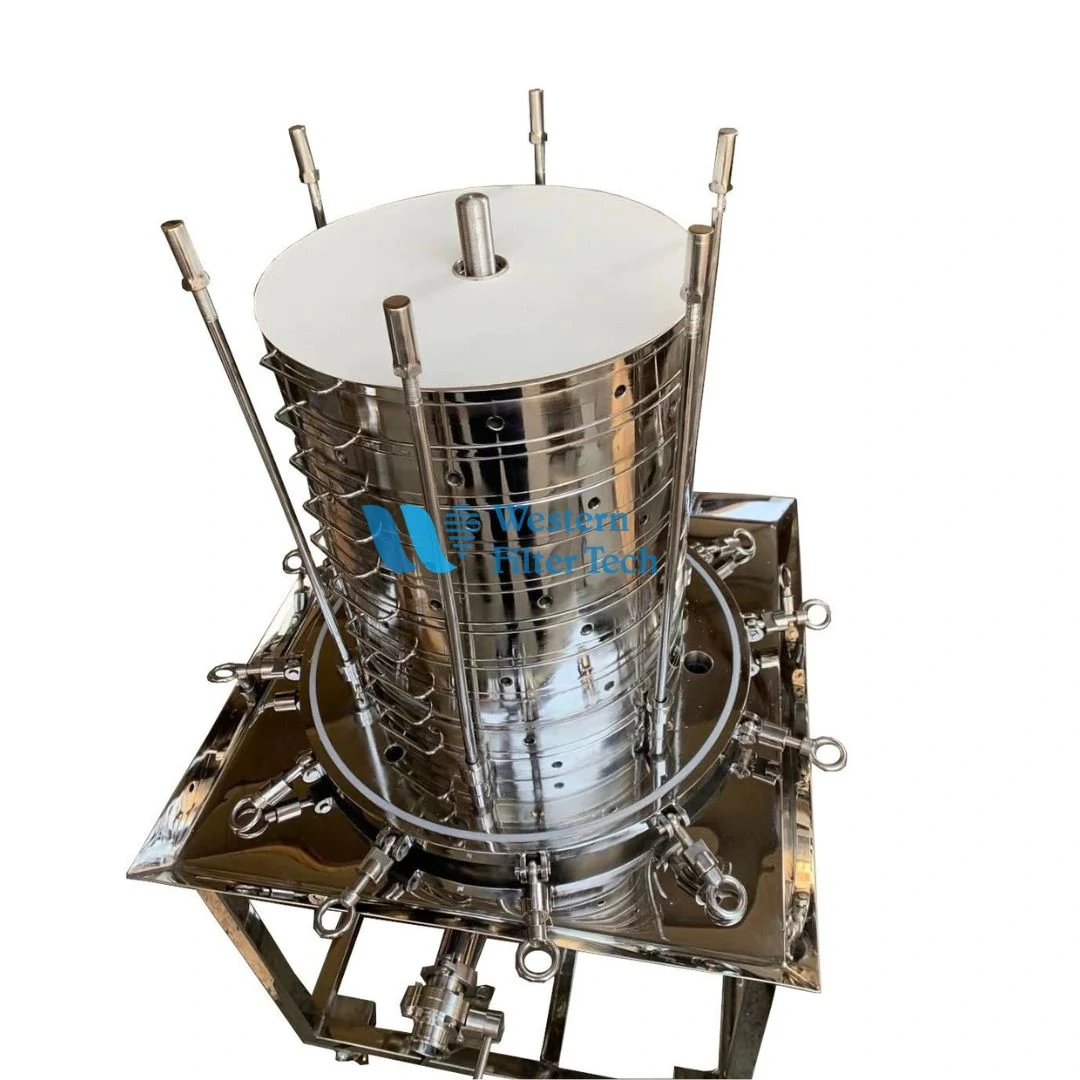

Sparklers Filter It consists of a filter cylinder with a top cover and a suitable clamping device to ensure an airtight seal. Pressure gauge, outlet port, and safety valve are all placed on the top.

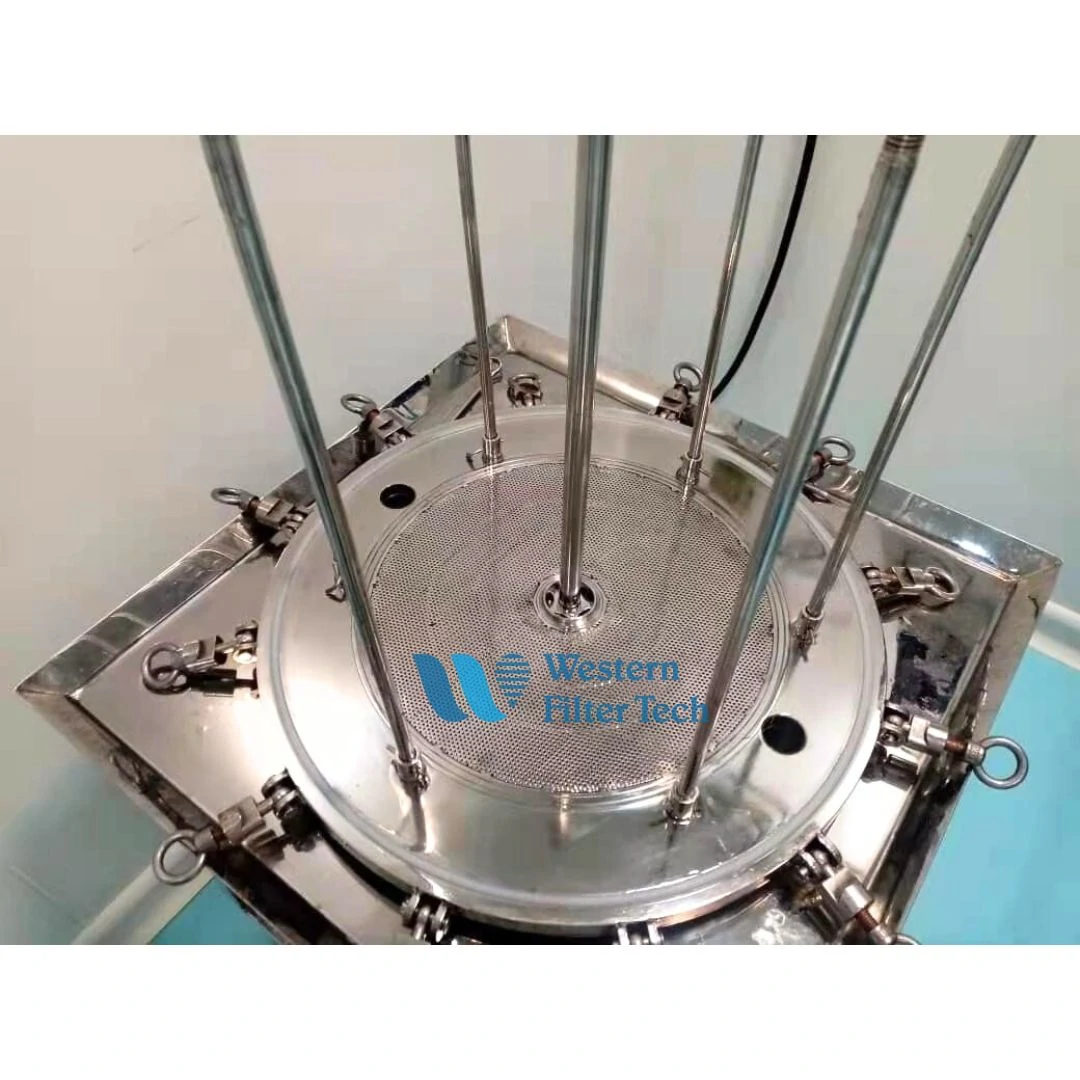

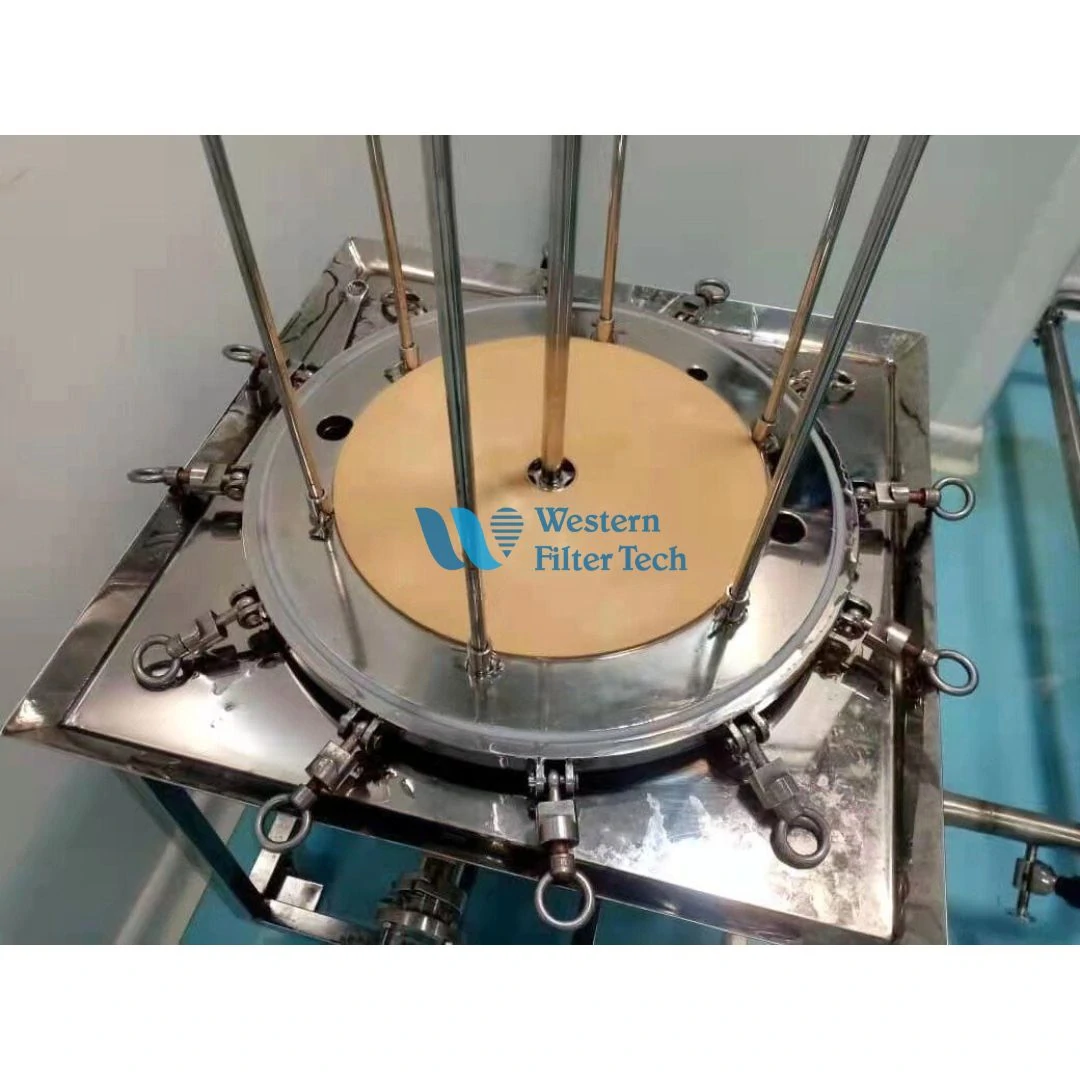

There is an integrated filter assembly inside the cylinder, forming the main filtration component of the entire device. The assembly includes multiple filter plates, perforated screens, filter media, inter locking cups, bottom assembly plates, and top clamping rings.

The entire assembly is connected together by side connecting bolts. With the help of a center bolt, the assembly is fixed to the main fuel tank.

Working Principle of Sparklers Filter

The working principle of the filter is to pump unfiltered liquid into the filter through positive pressure. The liquid is pumped into the filter media through open slots beside the filter plates. As the liquid pressure increases, solid particles are retained on the filter media, allowing only the filtered liquid to flow through the main pipeline via compression lock cups.

The filtration process continues until the filter cake reaches the machine’s capacity or the filtration rate nearly stops due to cake resistance.

The filter cake can be completely recovered by passing air or an inert gas through the bottom inlet to dry the cakes and obtain a clean empty vessel.

3, Advantages of Sparklers Filter

- The sealed design prevents evaporation, oxidation, and leakage.

- Different options of filter plate sizes are available, including deep filter plates for larger cake storage capacity and shallow filter plates for smaller cake storage capacity.

- Equipped with cross screens to prevent filter cakes from falling or breaking, providing optimal filtration quality.

- The filtration area and cake storage capacity can be customized (increased/decreased) according to process requirements.

- Sliding assembly ensures mobility and compactness.

4, Technical Specifications Sparklers Filter

| Specification | Filter area(m2) | Capacity(L) | Flow(L/H) |

| 8’’ Dia x 6 plates | 0.2 | 4.2 | 450-500 |

| 8’’ Dia x 8 plates | 0.25 | 5.6 | 600-700 |

| 14’’ Dia x 8 plates | 0.65 | 22 | 1300-1500 |

| 14’’ Dia x 10 plates | 0.81 | 27 | 1500-1700 |

| 18’’ Dia x 8 plates | 1.15 | 51 | 2500-3000 |

| 18’’ Dia x 12 plates | 1.72 | 76.5 | 4000-4500 |

| 18’’ Dia x 15 plates | 2.15 | 40 | 5000-5500 |

| 18’’ Dia x 23 plates | 3.3 | 61.5 | 8000-8500 |

| 33’’ Dia x 7 plates | 4.01 | 105 | 9000-9500 |

| 33’’ Dia x 10 plates | 5.51 | 150 | 12500-13000 |

| 33’’ Dia x 14 plates | 7.52 | 210 | 17500-18000 |

Note:

- The above data just for reference

- All technical data according to formal drawing from Western Filter

5, Applications of Sparklers Filter

WESTERN FILTER’s Stainless Steel Sparklers Filters redefine the filtration process with their compact, lightweight, and robust design. They are highly suitable for filtering sugar, liquids, chemicals, oils, beverages, etc. The filters are securely assembled and leak-proof.

We are confident that with our highly skilled and dedicated technical team, we can provide you with innovative and breakthrough products that deliver high efficiency in practical applications.

>>> Hotline: 0909796560 (Ms. Thanh)

>>> Similar product: Stainless steel filter press X400 – Western Filter

>>> Fanpage Facebook: Máy Ép bùn Khung bản – Western Filter Tech

Reviews

There are no reviews yet.