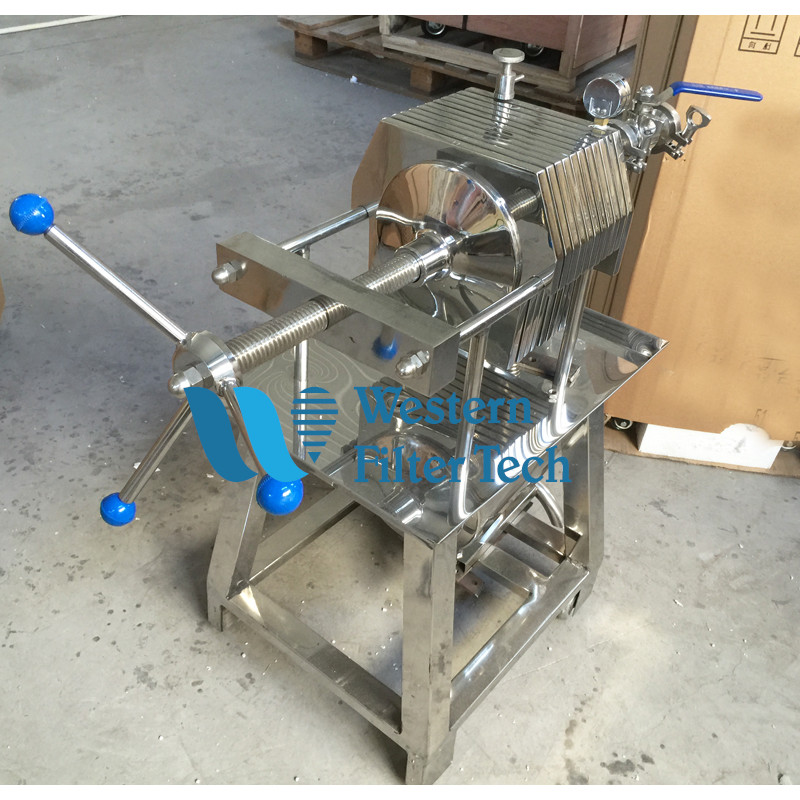

Stainless steel filter press X200 – Western Filter

DECRIPTION OF STAINLESS STEEL FILTER PRESS X200:

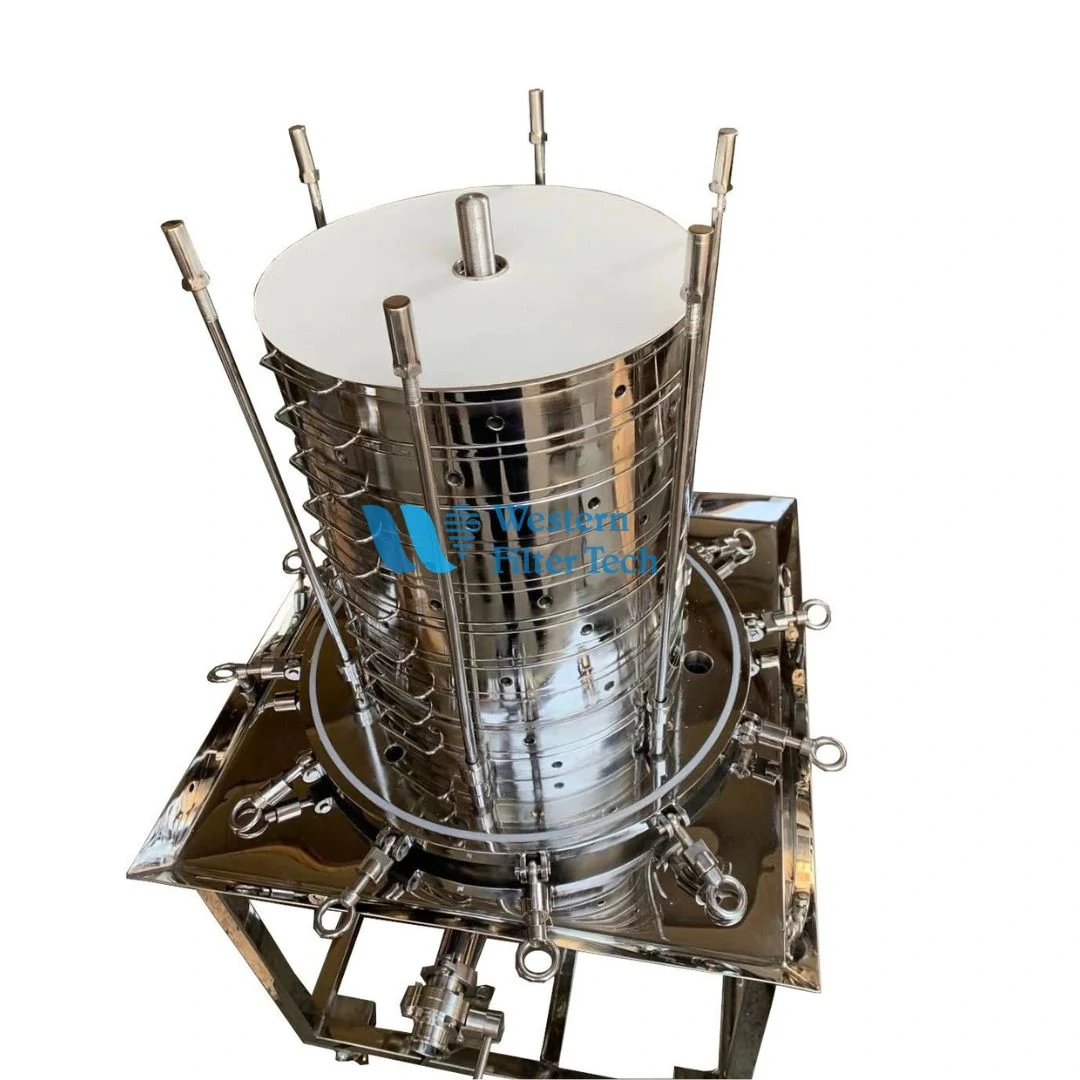

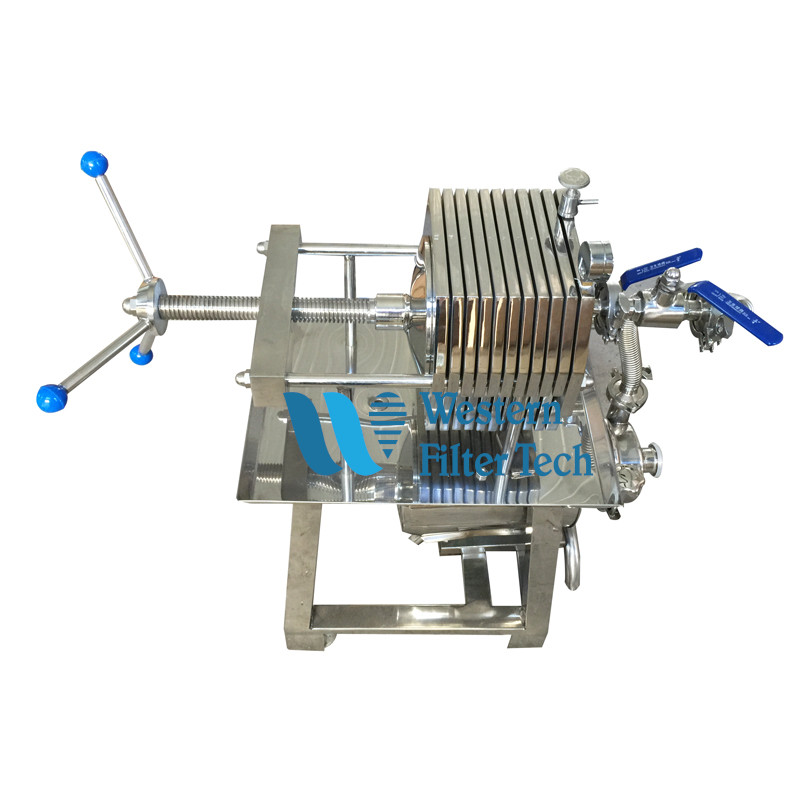

- The filter press products are made entirely of stainless steel, manufactured by Western Filter, and are available in cycle and plate types. Fabrication materials are SS304, SS316 and SS316L.

- The frame and plate filter press has two different types, one is completely stainless steel, the other is the machine frame is made of stainless steel, the filter plate is made of PP.

- It is widely applied in pharmaceutical, syrup, chemical, food, wine, beer, beverage industry.

SPECIFICATION OF STAINLESS STEEL FILTER PRESS X200:

- Basic features like a regular filter press but produce by stainless steel

- Resistant to acids, alkalis and temperatures (70 degrees Celsius)

- Elasticity and long life.

APPLICATION OF STAINLESS STEEL FILTER PRESS X200:

Stainless steel filter press is applied in many different fields such as: pharmaceutical industry, syrup, chemical, food, wine, beer, beverage. This machine is often used by customers to squeeze small capacity samples before deciding to buy large machines according to actual capacity.

ADVANTAGES OF STAINLESS STEEL FILTER PRESS X200:.

- Stainless steel filter press with a wide range of uses, especially for the industry that requires high product filtration and good sterilization.

- The filter press set is made of high quality stainless steel material, durable and anti-corrosion.

- The stainless steel filter can change the capacity according to the different requirements of the customer to select different frame sizes and can increase/decrease the number of frames of the filter press.

- Filter press with high pressure and good sealing, does not lose liquid and creates the clarity of the filtered liquid.

- High temperature resistant stainless steel filter press, non-toxic, clean and safe.

- The stainless steel frame press filter has the advantage of quick troubleshooting due to its ease of assembly and operation.

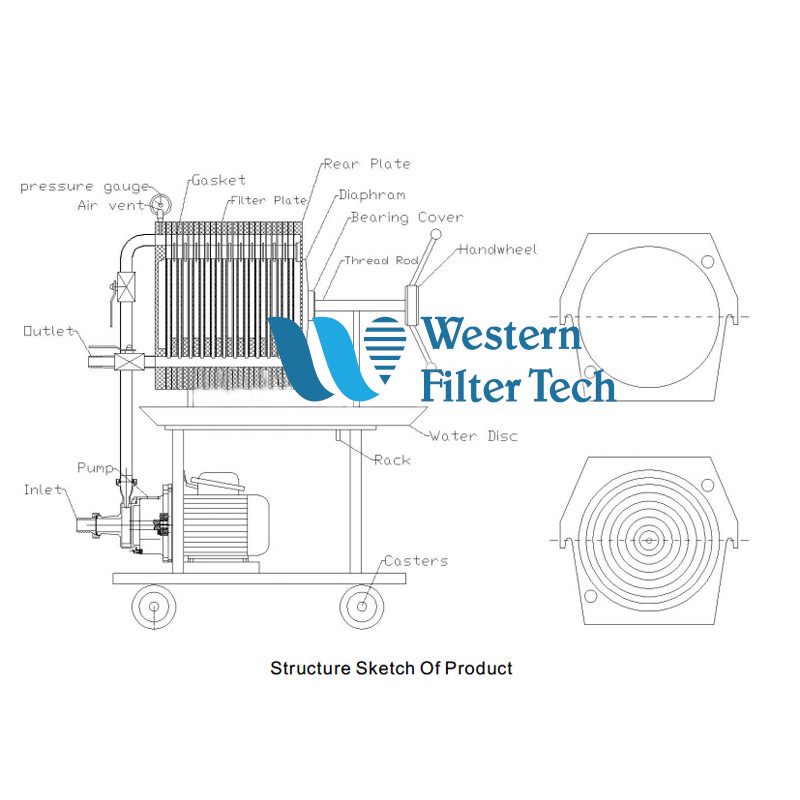

EQUIPMENT WITH STAINLESS STEEL FILTER PRESS X200:

This stainless steel filter press is specially equipped with a complete set because the accompanying equipment is rarely found outside the market, usually a standard filter press includes the following items.

- Complete filter press: stainless steel plate frame, filter cloth, stainless steel machine frame.

- Hydraulic manometer.

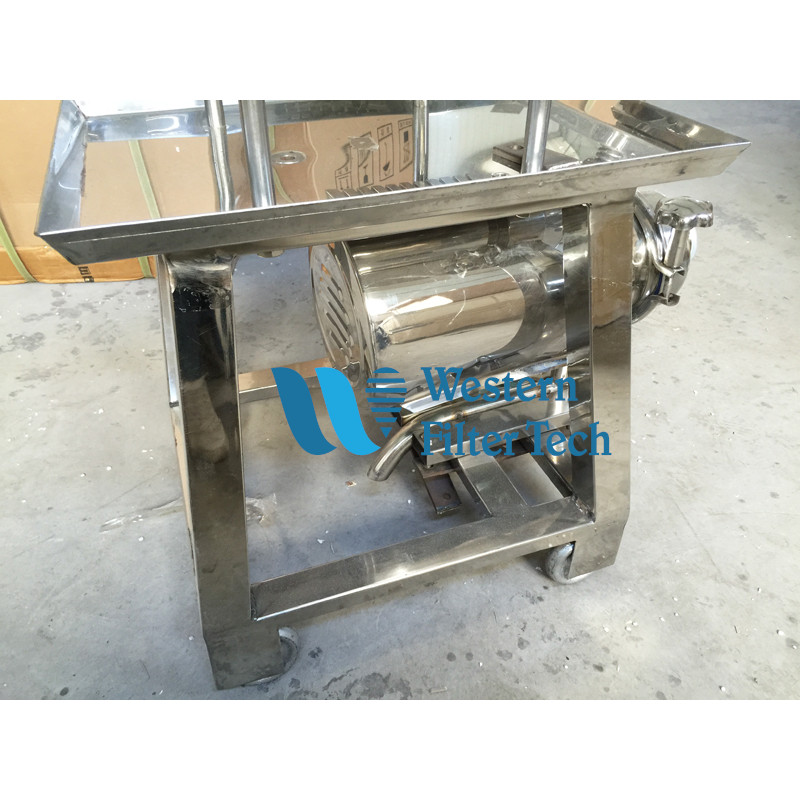

- Inlet feeding pump.

- Stainless steel pipe for feeding and draining with clamp connection.

- The seal o’ring are silicone

- Close and open filter press by manual or by hydraulic pump

The filter press has a simple structure, consisting of many filter plates covered with a layer of filter cloth. Depending on the capacity of the filter press, the number of filter plates will change. The filter plates will be compacted to form many space call as chambers containing sludge cake.

The sludge is coagulated and flocculated before being pumped into the filter chambers of the machine by a high-pressure pump (pneumatic diaphragm pump – or screw pump). During the process of feeding slurry into the machine, on the surface of the filter cloth in the cavity, separation will occur. Solid sludge particles will be retained on the surface of the filter cloth while water will penetrate and escape through the pipeline.

When the sludge has accumulated and filled the filter chambers, the sludge pump is turned off. The plates will be separated automatically or manually to remove the sludge cake. The filter cloth will be washed automatically or manually to continue the new filter cycle.

With the production characteristics and economic conditions in Vietnam today, the filter press designed and manufactured by Western Filter Technology Co., Ltd. is a reasonable choice with the product price is low. Much cheaper than imported products.

The design and manufacturing characteristics of the machine are relatively suitable for the current scale of sludge treatment in Vietnam, while the quality of the equipment is not inferior to that of imported products and especially imported products. After-sales service warranty policy is extremely fast and professional.

SOME PICTURES OF STAINLESS STEEL FILTER PRESS X200:

WESTERN FILTER TECHNOLOGY warranty one year filter press machine as well as for products after handover and technical support to solve all problems arising when using the company’s products. Products with manufacturing defects will be refunded according to the agreed contract value.

Model selection of stainless steel filter press X200:

- Manual operation

- Semi-automatic operation

- Automatic operation

We are proud to be a professional manufacturer of slurry filter presses in Vietnam with a team of dedicated and well-trained engineers, so your company can rest assured in the stages of technology consulting, Equipment selection as well as after-sales service are carried out by us with the highest concentration and responsibility.

We have a sample filter press machine that can be tested for free before the company decides to invest. Contact Western Filter Technology for all your sludge problems.

Video for machine operation principles – Western FIlter

Video for automatic filter cloth washing – Western Filter

>>> Similar product: stainless steel filter press X600

Reviews

There are no reviews yet.