Choose an air compressor for a diaphragm pump

Contents

Introduction to compressed air diaphragm pumps

When it comes to diaphragm pumps and compressed air, you probably have an idea that these pumps use diaphragms (2 or 4 diaphragms) to transfer fluid from point A to point B. The power source for these pumps is compressed air, not electricity.

That’s right, the pump operates solely on the compressed air provided by an air compressor. Therefore, diaphragm pumps will not be able to function without an air compressor

AODD pump

Introducing the air compressor

The air compressor is the “life force” of the diaphragm pump. Not only that, the air compressor also plays a crucial role in various industries.

Choosing the most suitable air compressor for your needs is essential, as it will help you optimize operating costs, ensure stable operation of diaphragm pumps and other pneumatic devices, and prevent future minor issues.

So how do you choose an air compressor that meets the requirements of a diaphragm pump? Let’s take a look at the TOP 1 method of choosing an air compressor that Western Filter applies in most cases!

Choosing the smartest air compressor for diaphragm pumps

Understanding the pump characteristic curve

An air-operated double diaphragm (AODD) pump requires a significant amount of compressed air. Essentially, we need to keep the valve open while the AODD pump is running. Therefore, our goal is to have an air compressor that can keep up with the air consumption.

With the same amount of compressed air, this type of diaphragm pump can push more fluid than another type of diaphragm pump with similar specifications. Therefore, the key to determining the size of the air compressor you need is to understand the “curve” of the pump.

It may seem like a complex art, but you only need to determine two things to fully understand and make the most accurate decisions.

1. Determine the flow rate of the pump

2. Determine the required operating pressure for the pump

With these two pieces of information, you now have a “working point” or an “ideal point” that you can apply to future decisions.

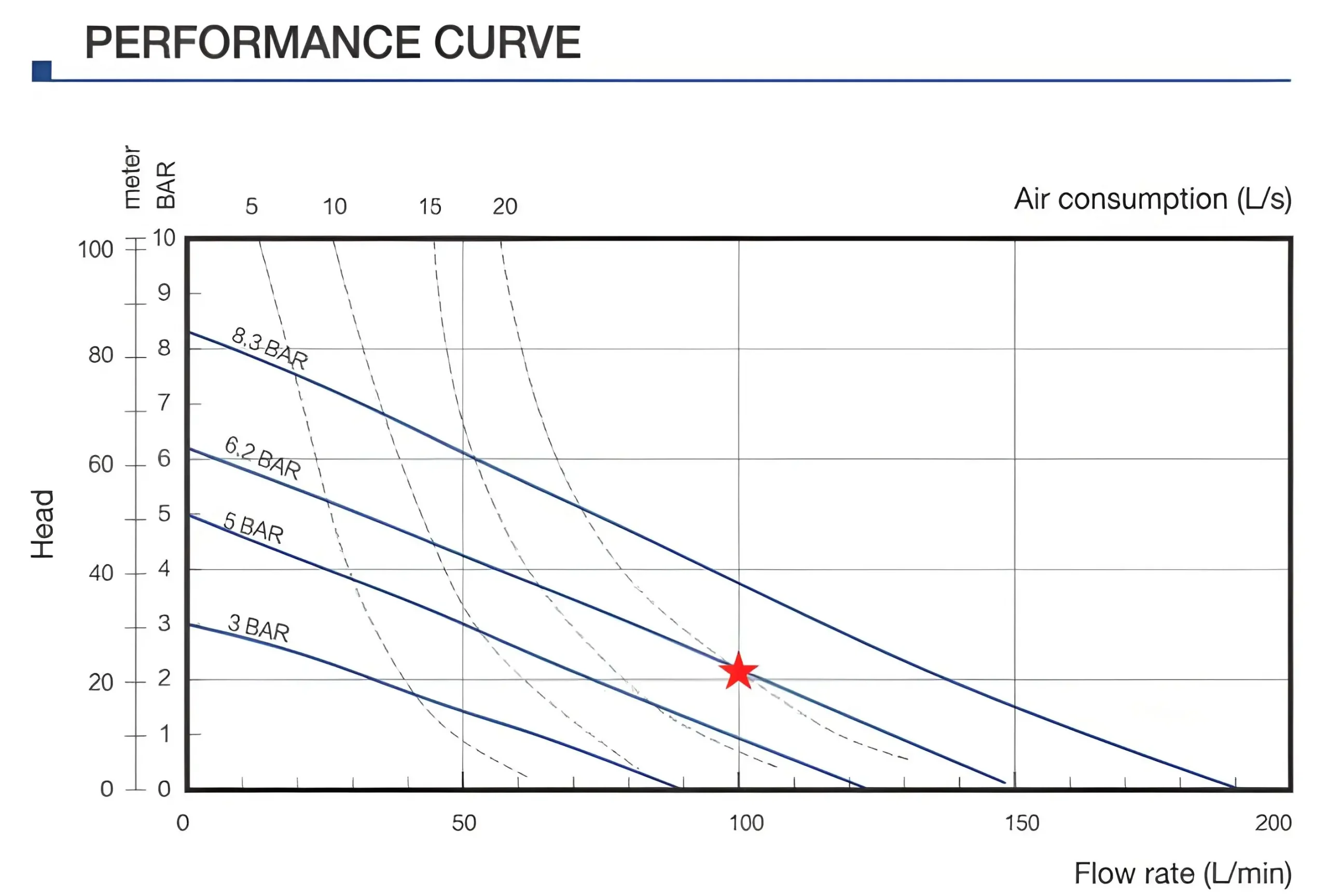

Let’s imagine that you have a working point from a 1-inch BSK diaphragm pump with a flow rate of 100 liters per minute and a working pressure of 2.2 bar. Let’s check how this ideal working point translates on the pump’s characteristic curve!

As you can see, on the characteristic curve of the BSK diaphragm pump, we have marked our ideal working point with a red star. This is the result of combining the pump flow rate and the required compressed air pressure. Luckily, this working point coincides with the intersection of two plotted curves (one dashed line and one solid line).

The dashed line represents the required compressed air flow rate (liters per second), and the solid line represents the required compressed air pressure (bar).

To determine the exact type of air compressor you need, you simply need to trace back to the first value of both curves. You will find that the dashed line leads you to an air flow rate of 20 liters per second, and the solid line is at 6.2 bar.

Therefore, in this case, an air compressor capable of producing a flow rate of 20 liters per second (1,200 liters per minute) at a compressed pressure of 6.2 bar is the perfect match for your diaphragm pump. Provide this information to an air compressor supplier, and they will recommend the most suitable type of air compressor for you.

AODD pump

Now you might be wondering, “What will happen if my working point does not conveniently intersect with two of the pre-drawn lines on the curves?” That’s a smart question!

The truth is, I cheated a bit by using an existing point. But the answer is, it’s easy to find any working point on a curve!

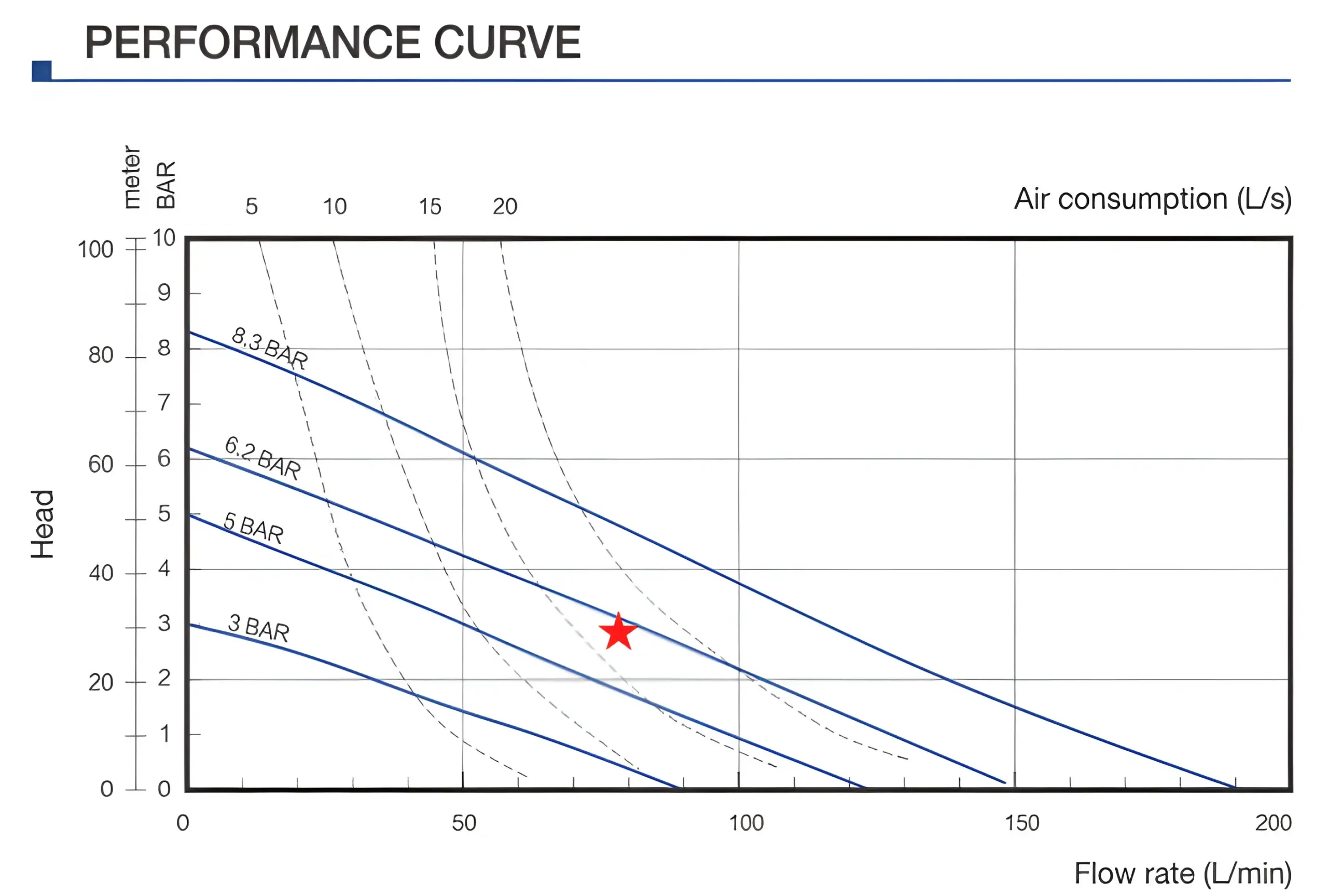

Let’s imagine you need to achieve a compression pressure of 3 bar and a flow rate of 80 l/s. Let’s together explore your ideal working point.

No specific line passes through that point!

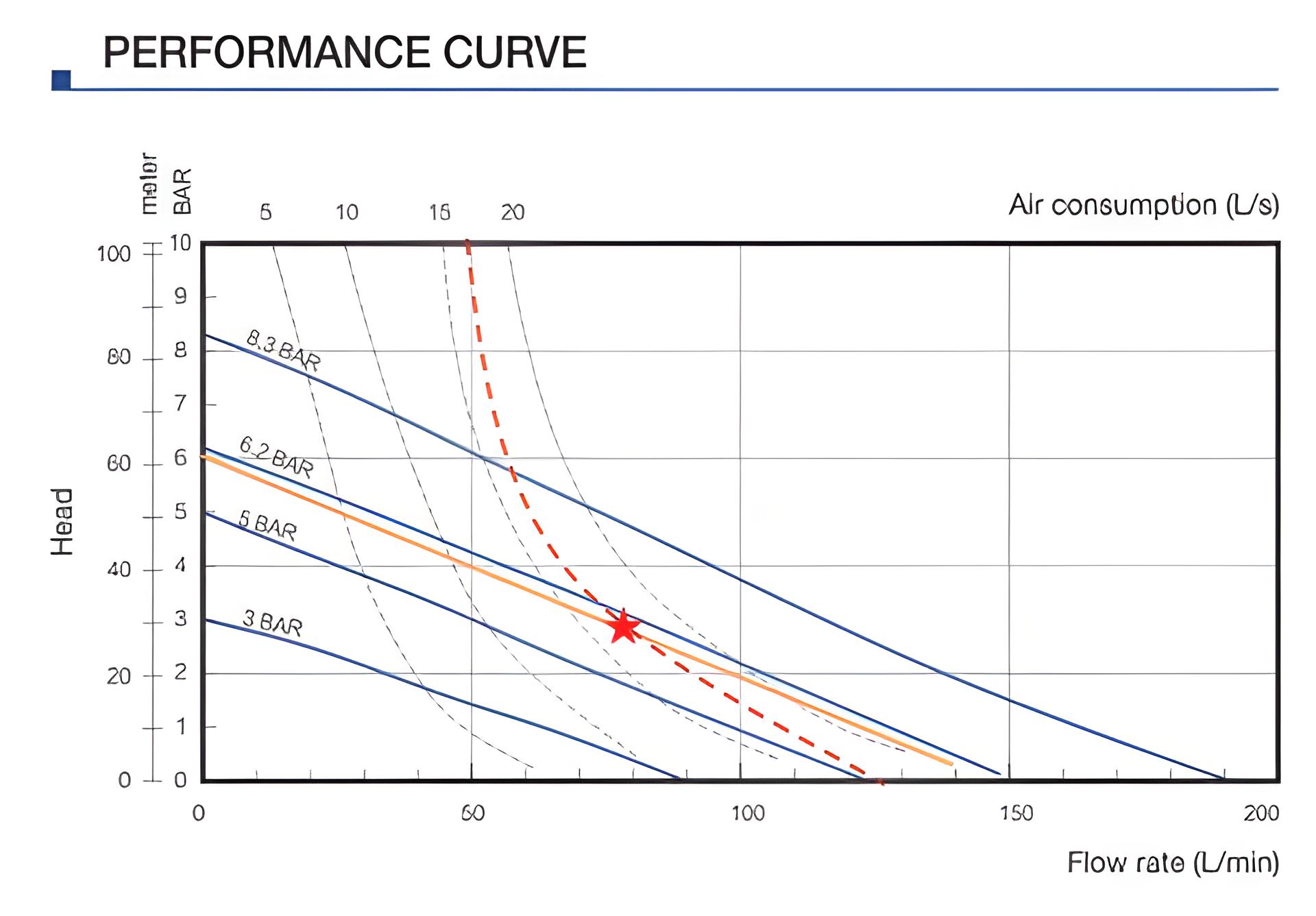

Don’t worry, you can use your imagination, and we will easily see where the lines could go. Imagine it and draw it in!

Although not perfect, it gives us a good idea. The red dotted line represents the gas flow, ranging from 15 to 20 l/s. The solid orange line represents the pressure, falling around 6 bar. In this case, you would need a compressor capable of producing around 17 l/s at 6 bar. It’s not too difficult to find!

Lastly, if you are running multiple diaphragm pumps or other compressed air devices for your system, create a suitable data sheet and work with air compressor suppliers to introduce the most suitable machine for the flow rate you need.

Important note before making a decision

In the above case, we chose a 1-inch pump (with a maximum flow rate of 192 l/s), which is entirely reasonable for the required pumping rate of 80 l/s.

However, if you want to pump a larger volume of around 180 l/s or more, then you will need more compressed air. Your pump will have to operate at maximum capacity for extended periods, leading to quick wear and tear of the diaphragm.

At this point, you should consider using a larger-sized diaphragm pump, such as the BSK 1.5-inch pump (with a maximum flow rate of 378.5 l/s), if it still fits within your budget, to avoid such unfavorable situations.

Conclusion

The air compressor is an essential component of the diaphragm pump. Selecting the most suitable air compressor for your diaphragm pump is crucial.

The smartest way to choose an air compressor is to read the pump’s characteristic curve. From there, you can make the most accurate decisions based on the needs of each business in general and the needs of each individual in particular.

If you still have questions about how to read the graph and the selection criteria, contact Western Filter now for assistance!

>> Contact now: 0909796560 (Ms. Thanh) for more advice

>> You may be interested Cách chọn bơm màng khí nén chuẩn nhất 2022

>> Visit fanpage Facebook of Western Filter Tech