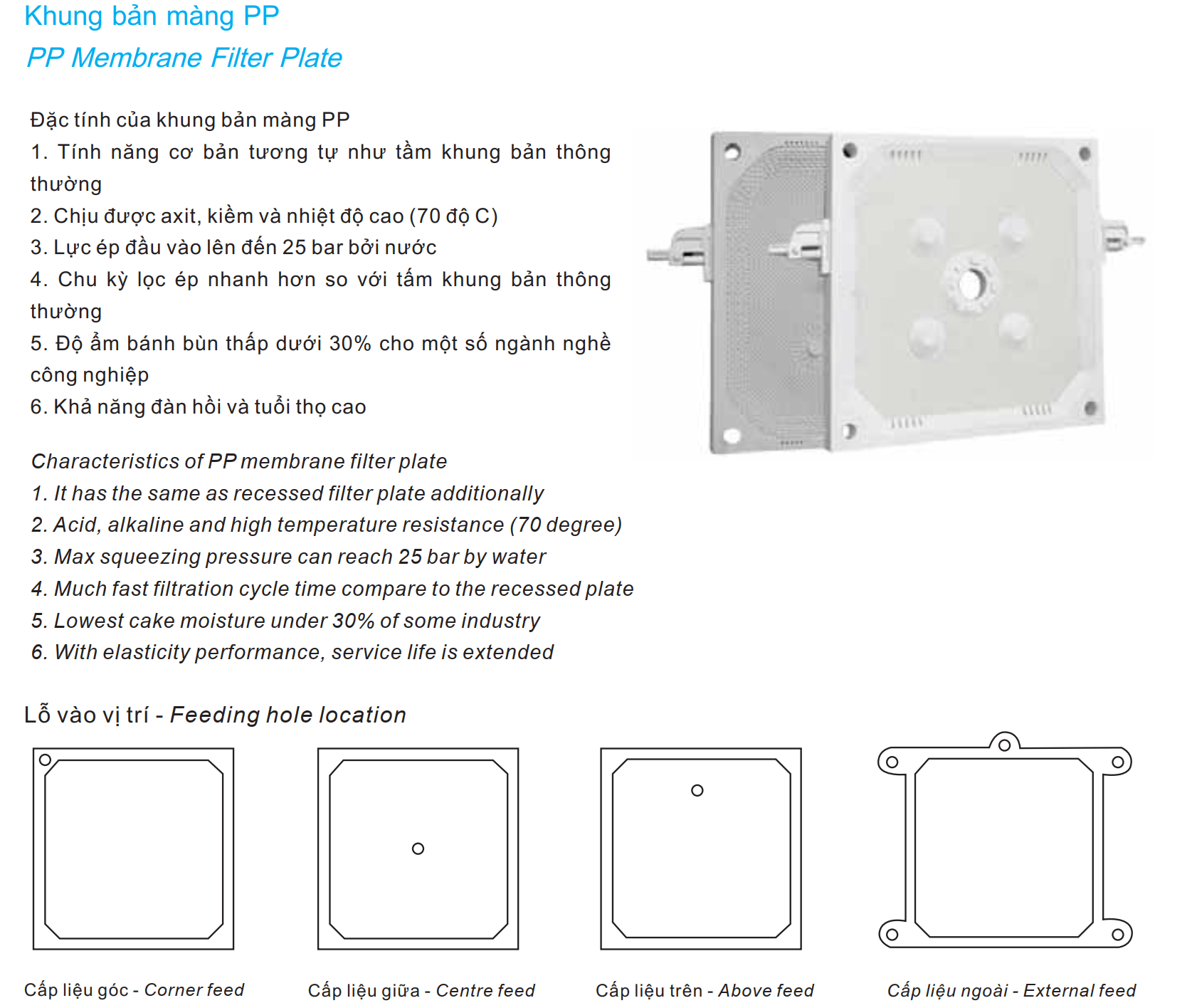

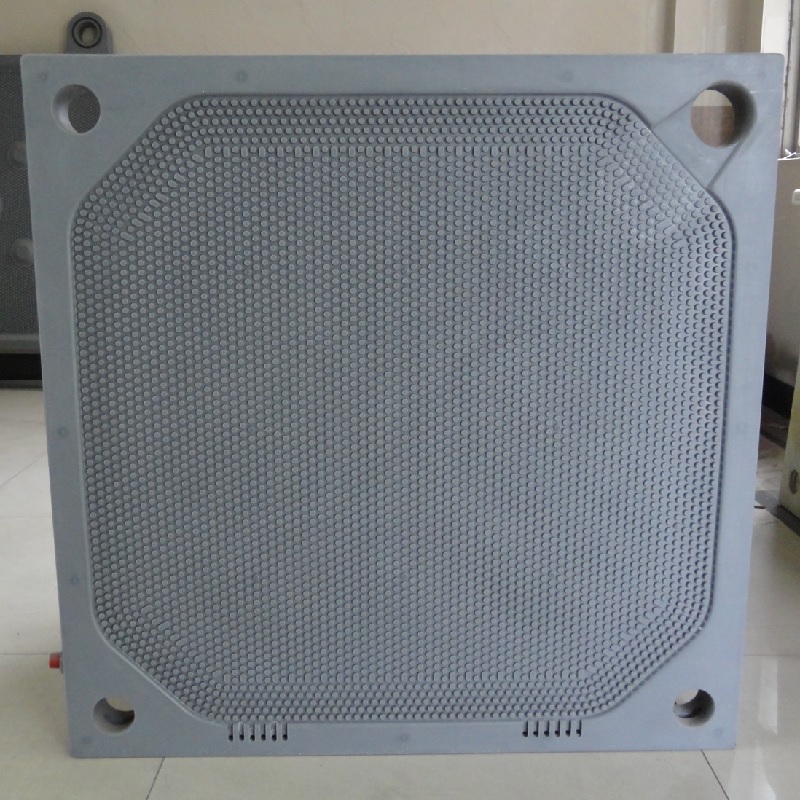

PP Membrane Filter Plate

DESCRIPTION

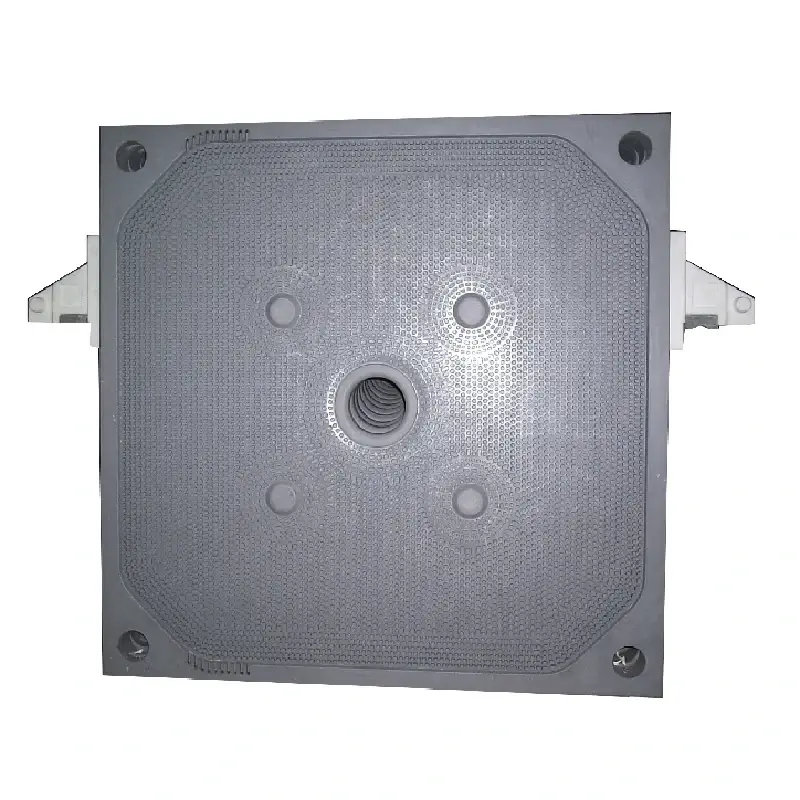

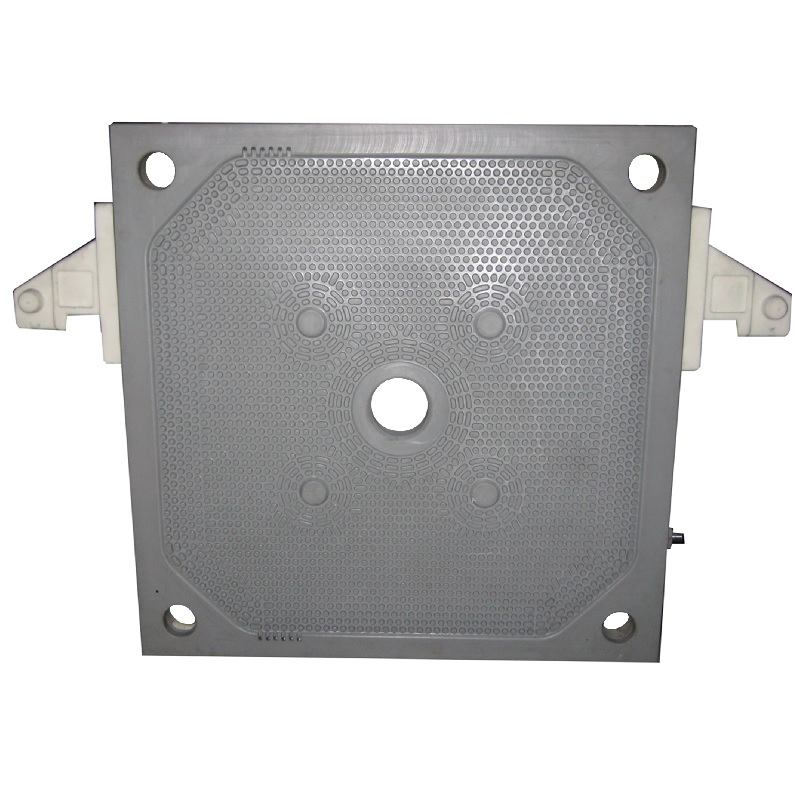

This type of plate is formed by a rigid structure and a flexible membrane fixed to it around the perimeter.

MAIN ADVANTAGES:

- Decrease filtration cycle times

- Reduce the residual moisture level in the cake

- Aumentan la homogeneidad de la torta

- They withstand high filtration pressures

- Suitable for filtrations at high temperatures

OPERATION:

When closing the filter press to pressure, the plates form chambers into which the product to be filtered is introduced. The solids are retained in the interior and the liquid is evacuated through the exit orifices. When the chamber is full the permeability decreases and a dry cake with the solid content is formed.

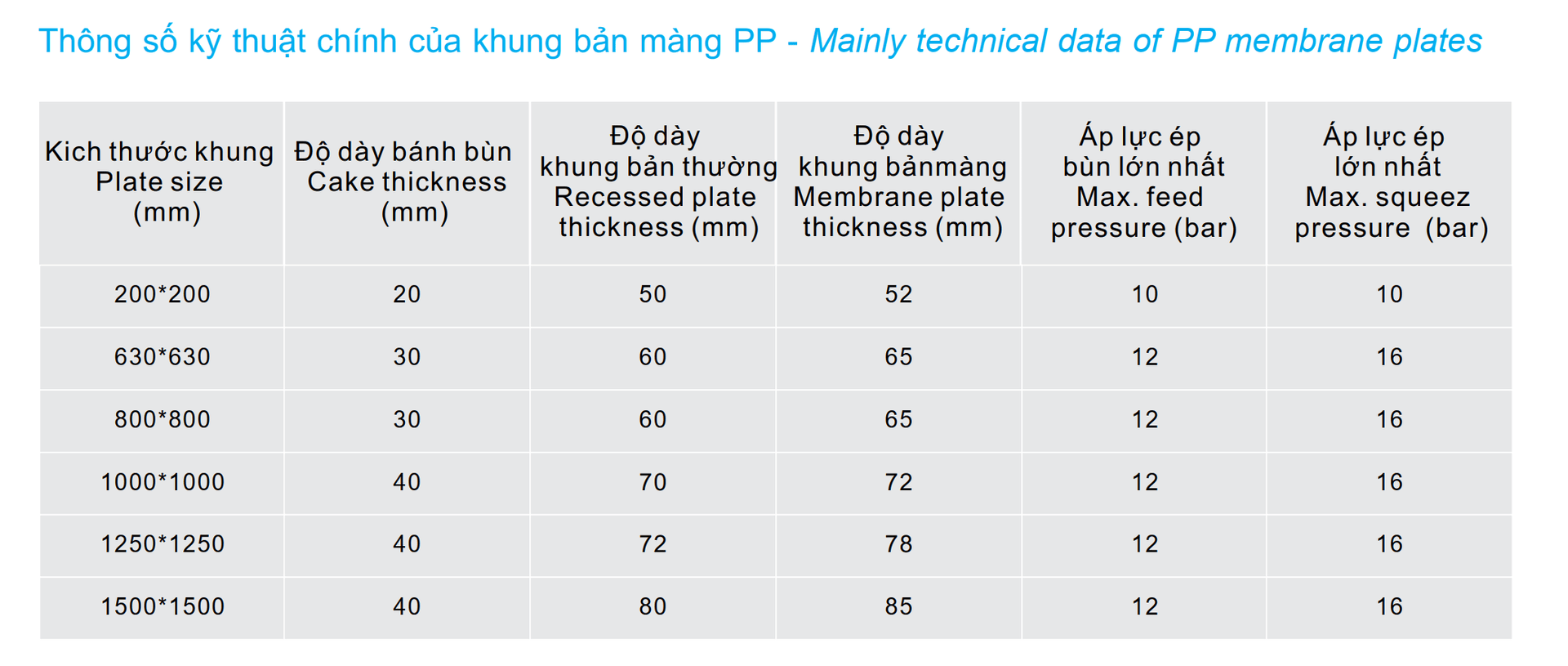

TECHNICAL DETAILS:

FORMAT:

- Standard sizes from 250 mm up to 2000

CONFIGURATION:

- Open or closed with different feeding options.

PRESSURE:

- Maximum standard filtration pressure up to 15, 20 bar.

TEMPERATURES:

- Minimum / maximum temperature: from – 10 up to + 70 Cº

MATERIALS:

- Polypropylene homopolymers / Copolymers

- Polypropylene homopolymers / FDA Copolymers

- Anti-static polypropylene

- PVDF

- Antistatic PVDF

- Other materials upon request

- Membranes are available in thermoplastic elastomers, EPDM, NBR, FKM.

- Membrane materials: PP, PVDF, PTFE, etc.>

- Removable membranes.