Center feeding pipe for filter press – Western Filter

INTRODUCE CENTER FEEDING PIPE

The slurry center feed pipe assembly will last for many years in the same way that any other type of water hose can. However, if the material of the slurry press center feed pipe is not hard enough to handle the corrosiveness of the fluid flowing through the slurry press, the middle manifold assembly may corrode.

For high temperature or corrosive materials, please provide special properties to us prior to machining. We can upgrade to CPVC, Carbon Steel, 304 or 316SS Stainless Steel and Titanium. Western Filter can also provide additional manifold upgrades such as automatic valves.

STRUCTURE OF CENTER FEEDING PIPE FOR FILTER PRESS

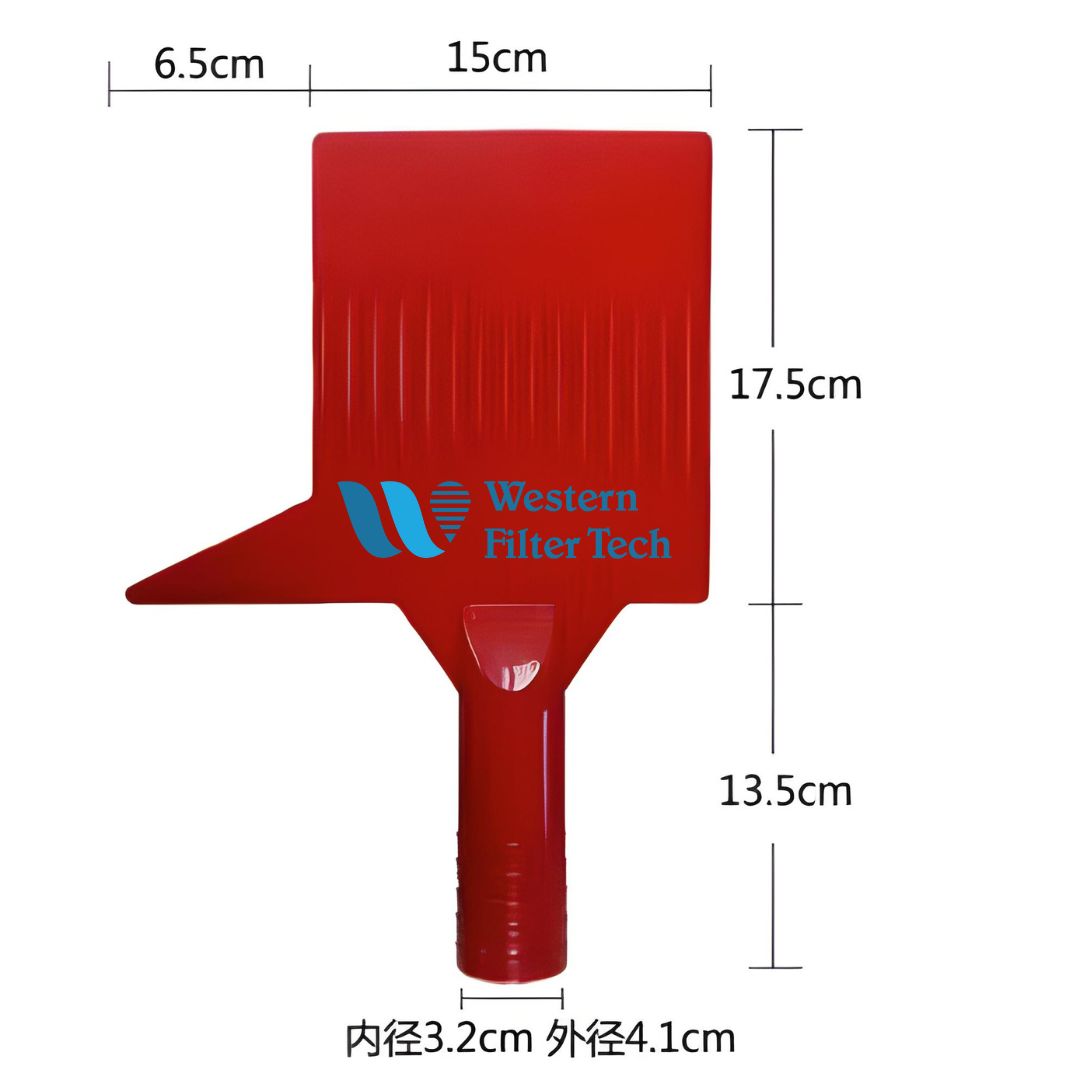

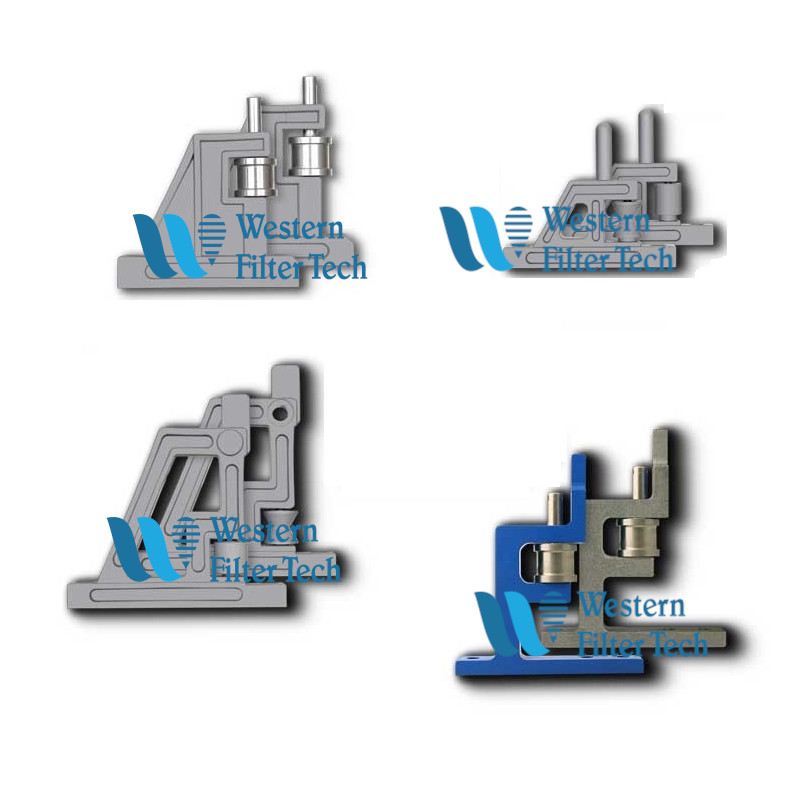

The central feed pipe is what connects the slurry press to the product to be filtered. The slurry press center feed pipe assembly consists of five different parts.

- The first part is a locking nut that fastens to the central feed pipe and connects to the outside of the press.

- The pipe, which is the second part, passes through the top of the filter and through the head plate of the filter press.

- The third part of the central feed hose assembly is a gasket that ensures the hose assembly is watertight.

- Next, is the seat nut clamp that secures the assembly of center feeding pipe to the head plate. This part of the assembly will always stay in place unless you replace the assembly or one of its parts.

- The last part, the cloth clamp nut, will be removed as often as it is screwed into the cloth clamp nut after the top panel is installed. Webbing straps need to be tightened to keep the fabric in place.

CENTER FEEDING PIPE ASSEMBLY FOR FILTER PRESS

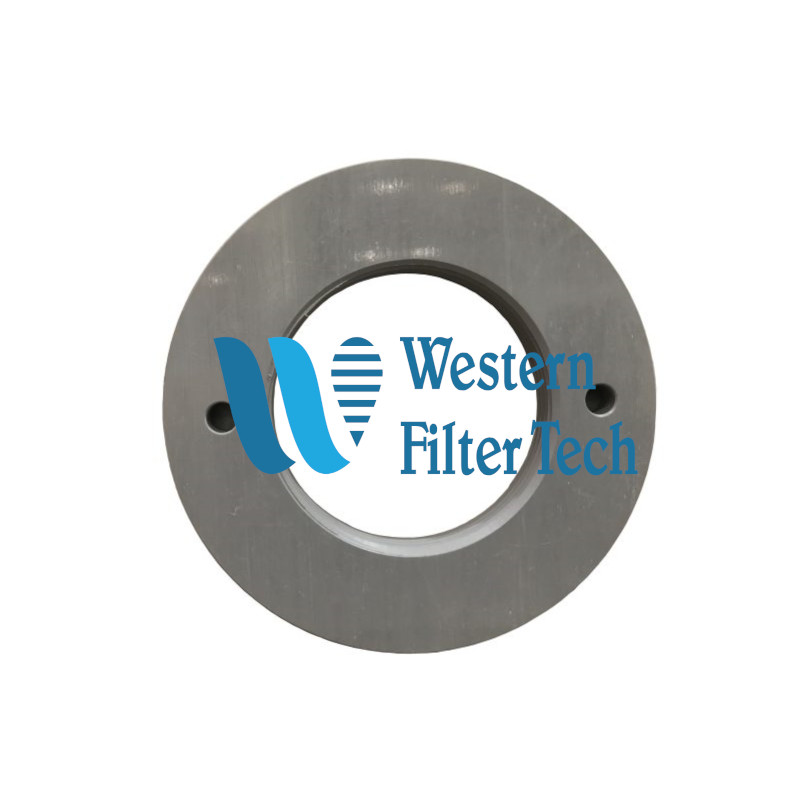

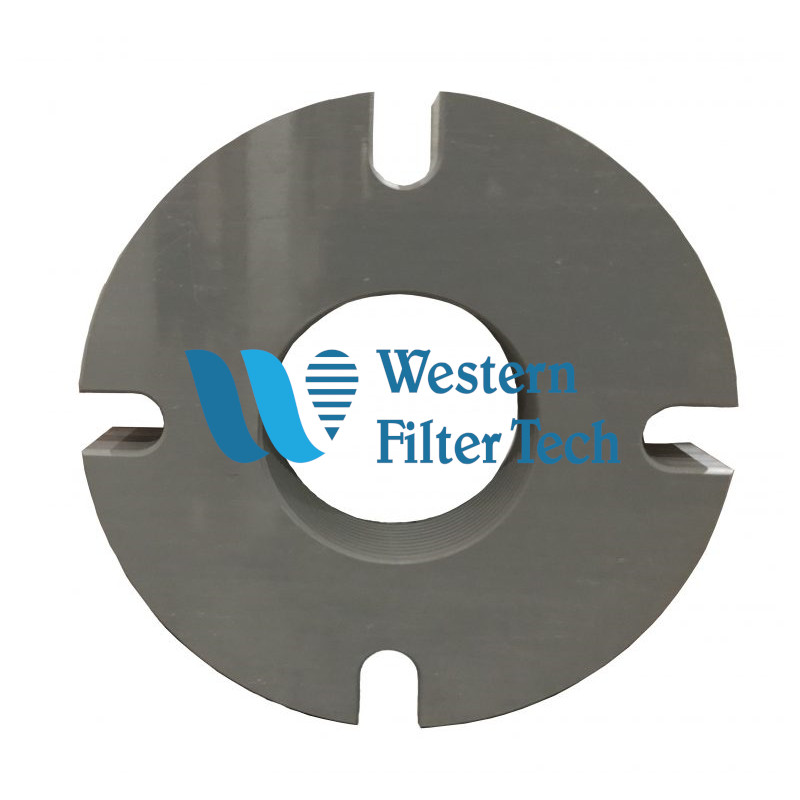

- 1 Nut block

- 1 Nut clamp

- 1 Seat Nut

- 1 Gasket

- Made of quality CPVC – SS304 – SS316

- Durable, anti-corrosion

- For hot or cold water flow

- Standard tube sizes: 1.5 inch, 2 inch, 3 inch and 4 inch

>>> Similar product: PP handle for filter press

>>> Fanpage Facebook: Máy Ép bùn Khung bản – Western Filter Tech